Reliable Supplier Boiler Operating - Coal Boiler Biomass Boiler Slag Remover – Double Rings

Reliable Supplier Boiler Operating - Coal Boiler Biomass Boiler Slag Remover – Double Rings Detail:

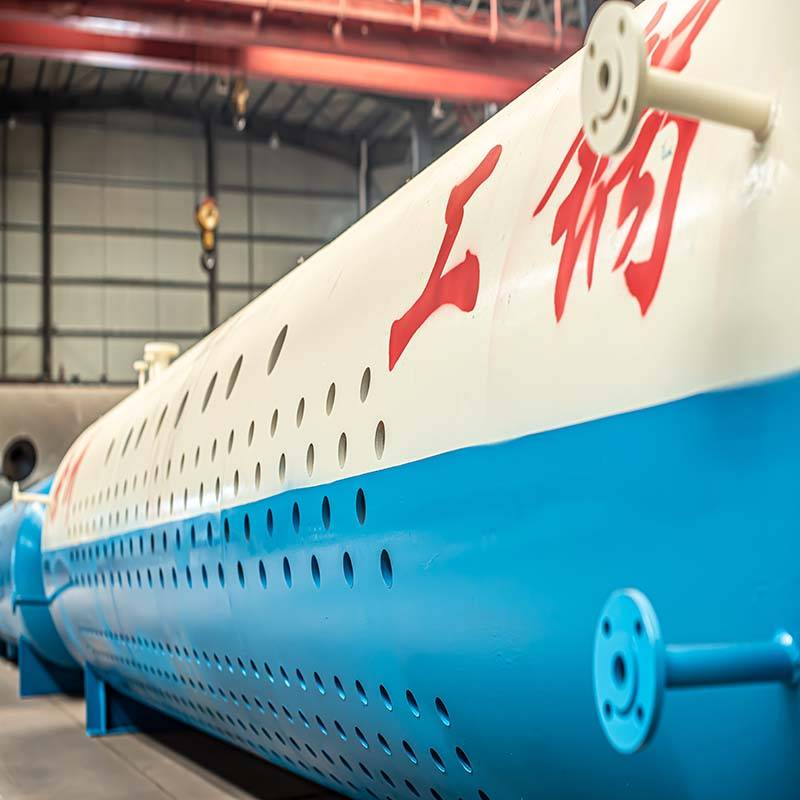

Slag Remover used in Coal Boiler

Introduction

The Slag Remover is a kind of boiler slag tapping equipment. The carbon slag produced after the coal is burned in the boiler is pushed to the slag storage pit by the grate, and is dragged out of the furnace by the slag machine to clear the slag accumulation.

Technology

The high-temperature slag discharged from the furnace is first crushed into small pieces by a pair-roller slag breaker, which is convenient for cooling and transportation; the crushed slag enters the water-cooled spiral slag discharger and the spiral blades and outer cylinder are fully exchanged. The heat is discharged after cooling. If necessary, an air lock (star ash unloading valve) can also be configured at the outlet of the slag cooler. The ash inlet temperature is less than 900℃, the slag size is less than 100MM, the conveying distance is 4-7M, horizontal installation.

Advantage

1. It is convenient for comprehensive utilization of slag.

2. Reasonable structure design, reliable operation, safe operation and good sealing performance.

3. Good load adaptability and convenient for remote control.

Product detail pictures:

Related Product Guide:

Boiler Structure

Our concentrate on should be to consolidate and enhance the quality and service of present products, meanwhile consistently produce new products to meet unique customers' demands for Reliable Supplier Boiler Operating - Coal Boiler Biomass Boiler Slag Remover – Double Rings , The product will supply to all over the world, such as: Rome, Bangladesh, Hyderabad, Our Company has qualified engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the items, Be sure to feel free to contact us.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!