High reputation Industrial Gas Boiler - Coal Boiler Biomass Boiler Reducer – Double Rings

High reputation Industrial Gas Boiler - Coal Boiler Biomass Boiler Reducer – Double Rings Detail:

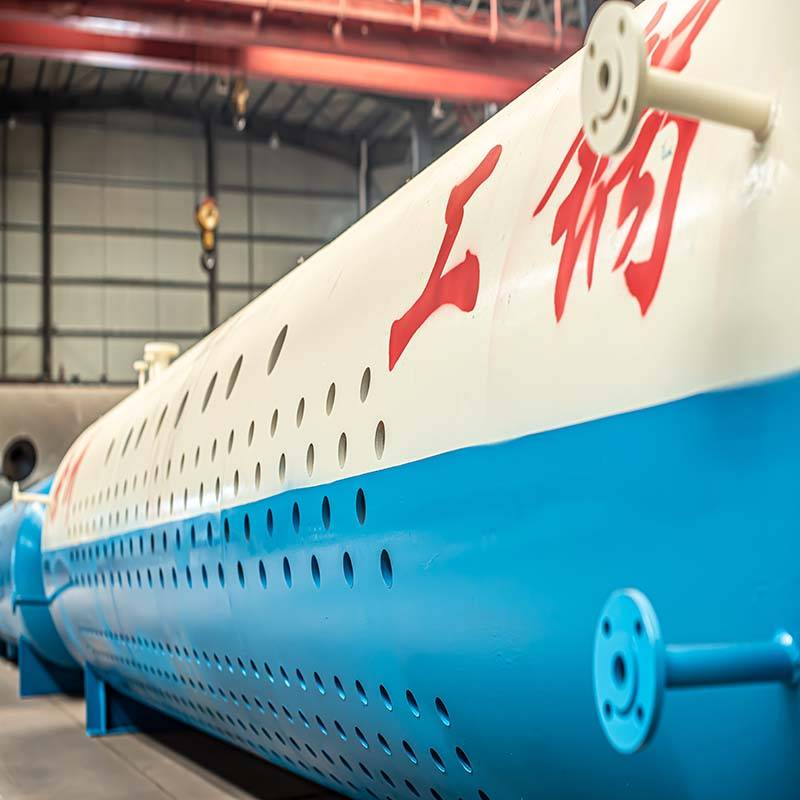

Reducer used in DR Boiler

• The main parts adopt high quality carbon structural refined steel.With high strength, high transmission efficiency and reliable operation, long service life, etc.

• Respectively using multilevel, stepless frequency conversion speed regulating mode. User can reasonably match speed reducer according to the different operation condition of boiler.With the features of easy operation, energy saving, etc

• With characteristics of large transmission torque and speed ratio, less consumed power,compact structure, and wide use.

Product detail pictures:

Related Product Guide:

Boiler Structure

"Based on domestic market and expand overseas business" is our development strategy for High reputation Industrial Gas Boiler - Coal Boiler Biomass Boiler Reducer – Double Rings , The product will supply to all over the world, such as: South Korea, Jamaica, Provence, Many goods fully conform to the most rigorous of international guidelines and with our first-rate delivery service you will have them delivered at any time and in any place. And because Kayo deals in the entire spectrum of protective equipment, our customers don't have to waste time shopping around.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!

Write your message here and send it to us