China Water Tube Boiler Factory - Coal Boiler Biomass Boiler Slag Remover – Double Rings

China Water Tube Boiler Factory - Coal Boiler Biomass Boiler Slag Remover – Double Rings Detail:

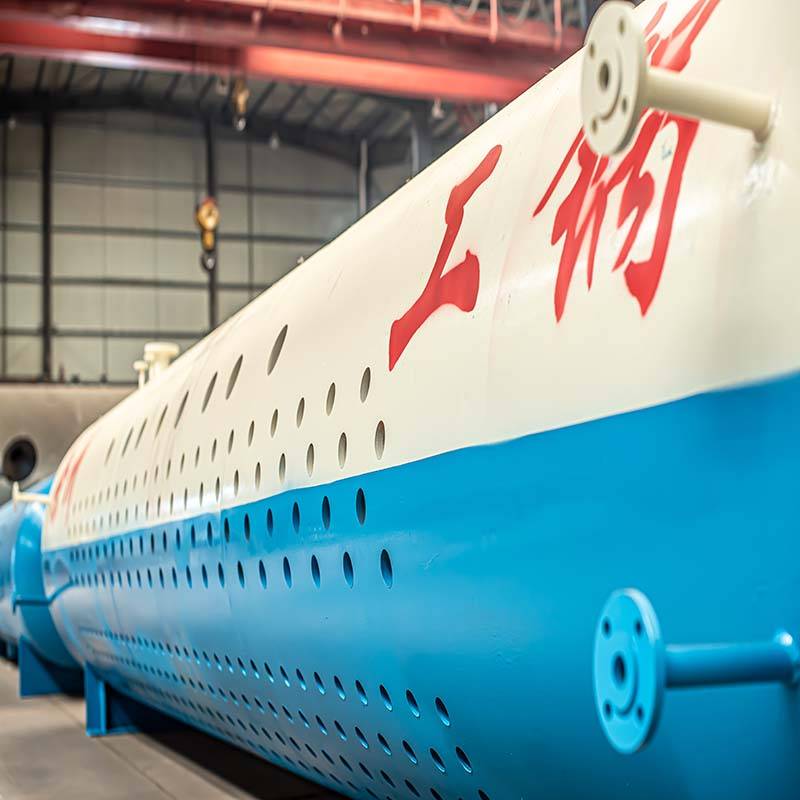

Slag Remover used in Coal Boiler

Introduction

The Slag Remover is a kind of boiler slag tapping equipment. The carbon slag produced after the coal is burned in the boiler is pushed to the slag storage pit by the grate, and is dragged out of the furnace by the slag machine to clear the slag accumulation.

Technology

The high-temperature slag discharged from the furnace is first crushed into small pieces by a pair-roller slag breaker, which is convenient for cooling and transportation; the crushed slag enters the water-cooled spiral slag discharger and the spiral blades and outer cylinder are fully exchanged. The heat is discharged after cooling. If necessary, an air lock (star ash unloading valve) can also be configured at the outlet of the slag cooler. The ash inlet temperature is less than 900℃, the slag size is less than 100MM, the conveying distance is 4-7M, horizontal installation.

Advantage

1. It is convenient for comprehensive utilization of slag.

2. Reasonable structure design, reliable operation, safe operation and good sealing performance.

3. Good load adaptability and convenient for remote control.

Product detail pictures:

Related Product Guide:

Boiler Structure

We emphasize advancement and introduce new products and solutions into the market each year for China Water Tube Boiler Factory - Coal Boiler Biomass Boiler Slag Remover – Double Rings , The product will supply to all over the world, such as: Burundi, Argentina, Hungary, Our company sets up several departments, including production department, sales department, quality control department and sevice center,etc. only for accomplish the good-quality product to meet customer's demand, all of our products have been strictly inspected before shipment. We always think about the question on the side of the customers,because you win,we win!

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.