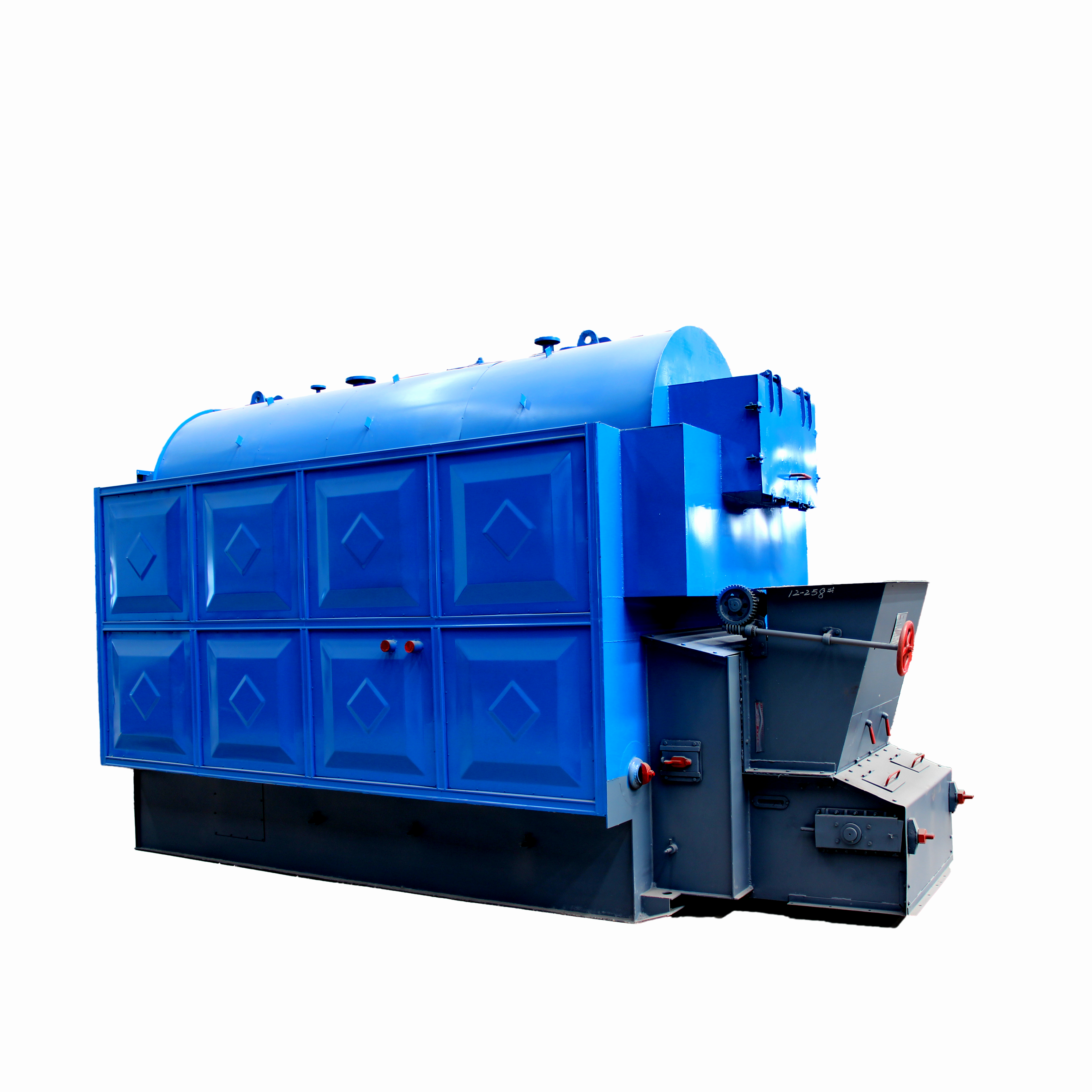

High Quality Electric Boiler - Single Drum Hot Water Boiler – Double Rings

High Quality Electric Boiler - Single Drum Hot Water Boiler – Double Rings Detail:

Parameter :

DZG(L)Bearing Pressure Hot water boiler

Main Technology Parameter List

| Model | DZG0.7-0.7/95/70 DZL0.7-0.7/95/70 |

DZG1.4-0.7/95/70 DZL1.4-0.7/95/70 DZL1.4-1.0/115/70 |

DZL28-1.0/115/70 DZL2.8-1.25/130/70 |

DZL4.2-1.0/115/70 DZL4.2-1.25/130/70 |

||

| Rated Capacity T/h | 0.7 | 1.4 | 2.8 | 4.2 | ||

| Rated Working Pressure Mpa | 0.7 | 0.7/1.0 | 1.0/1.25 | 1.0/1.25 | ||

| Rated Steam Temp. ℃ | 95 | 95/115 | 115/130 | 115/130 | ||

| Feed Water Temp. ℃ | 70 | 70 | 70 | 70 | ||

| Fuel Consumption Kg/H | ~150 | ~310 | ~590 | ~900 | ||

| Thermal Efficiency % | 75 | 78 | 79 | 77.44 | ||

| Heating Surface | Boiler Body m² | 32.4 | 33.85 | 75.75 | 142 | |

| Economizer m² | 24.64 | 38.5 | 87.2 | |||

| Grate area m² | 1.4/2.05 | 2.3/3.5 | 4.66 | 7.4 | ||

| Designed Fuel Type | Bituminous Coal | Bituminous Coal | Bituminous Coal | Bituminous Coal | ||

| Max. Transport Weight T | ~16 | ~21 | ~26.5 | ~30 | ||

| Max. Transport Dimension m | 4.3×2.25×2.955.26×2.25×2.95 | 5.1×2.2×3.35.9×2.2×3.3 | 6.5×2.6×3.5 | 6.01×3.4×3.57.29×2.9×1.7 | ||

| Boiler Auxiliary Equipment Model and Specification | ||||||

| Air Blower | Model | T4-72-11;3.2A Right | T4-72-11;3.5A Right | T4-72-11;4A Right | T4-72-11;5A Right | |

| Motor Power | N=1.5 Kw | N=3 Kw | N=5.5 Kw | N=11 Kw | ||

| Draft Fan | Model | YX9-355C ; Right 0° | Y-9-26;6.3C ; Right 0° | Y-9-26;9D;Right 0° | Y8-399D;Ring 0° | |

| Motor Power | N=5.5 Kw | N=11 Kw | N=22 Kw | N=30 Kw | ||

| Gear Box | Model | GL-5P | GL-5P | GL-5P | GL-10P | |

| Motor Power | N=0.55 Kw | N=0.55 Kw | N=0.55 Kw | N=1.1Kw | ||

| Feed Water Pump | Model | 1.5WCT-120 | 1.5WCT-120 | 1½ GC5x5 | 2GC5x4 | |

| Motor Power | N=2.2 Kw | N=2.2Kw | N=5.5 Kw | N=11 Kw | ||

| Dust Remover | Model | XD-1 | XD-2 | XD-4 | XD-6 | |

| ModelItem | DZL7-1.0/115/70 | DZL14-1.0/115/70 | DZL29-1.25/130/70 | DZL46-1.25/130/70 | DZL58-1.25/130/70 | DZL70-1.25/130/70 | |

| Rated Capacity T/h | 7 | 14 | 29 | 46 | 58 | 70 | |

| Rated Working Pressure Mpa | 1.0 | 1.0 | 1.25 | 1.25 | 1.25 | 1.25 | |

| Rated Steam Temp. ℃ | 115 | 115 | 130 | 130 | 130 | 130 | |

| Feed Water Temp. ℃ | 70 | 70 | 70 | 70 | 70 | 70 | |

| Heating AreaBoiler Body m² | 228.6 | 434.7 | Radiation:73.07Convection:903.01 | Radiation:147.8Convection:1418.5 | Radiation:147.8Convection:1418.5 | Radiation:147.8Convection:1418.5 | |

| Grate area m² | 11.5 | 22.5 | 34.5 | 57.8 | 77 | 91 | |

| FuelKj/Kg | Coal | Class II Bituminous Coal | |||||

| Low heat | 18757 | 17693 | |||||

| Fuel Consumption Kg/h | ~1440 | ~2700 | ~6610 | ~10500 | ~12800 | ~15300 | |

| Thermal Efficiency % | 80 | 80 | 82.5 | 82.05 | 83.03 | 83.28 | |

| Max. Transport Weight Ton | 35 | 28 | 19.68 | 28.796 | 31 | 31 | |

Product detail pictures:

Related Product Guide:

Boiler Structure

We also offer product sourcing and flight consolidation services. We have our own factory and sourcing office. We can provide you with almost every type of product related to our product range for High Quality Electric Boiler - Single Drum Hot Water Boiler – Double Rings , The product will supply to all over the world, such as: Slovakia, Marseille, kazan, We will do our utmost to cooperate & satisfied with you relying on top-grade quality and competitive price and best after service ,sincerely look forward to cooperating with you and make achievements in the future!

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!

Write your message here and send it to us