China Biomass Steam Boiler Manufacturers - Biomass Hot Water Boiler – Double Rings

China Biomass Steam Boiler Manufacturers - Biomass Hot Water Boiler – Double Rings Detail:

Introduction :

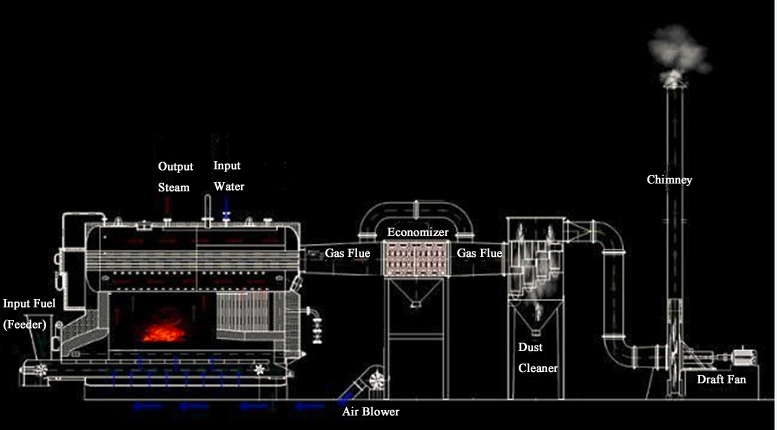

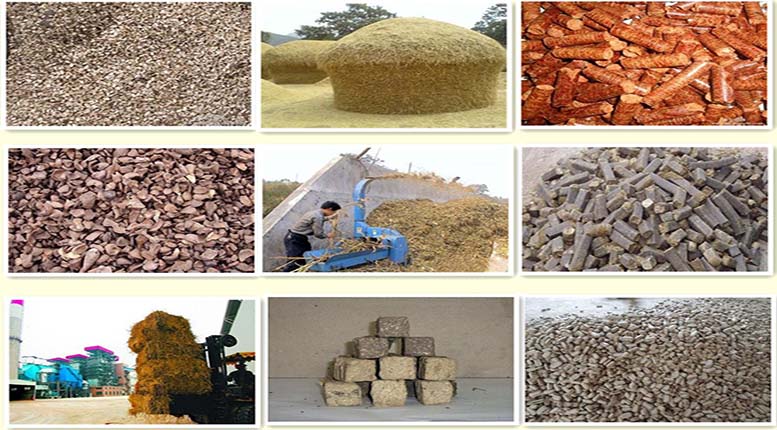

Biomass boiler is horizontal three-back water fire pipe composite boiler. The fuel can be Biomass,coal,wood,rice husk,shells,pellets,bagasse,waste etc..

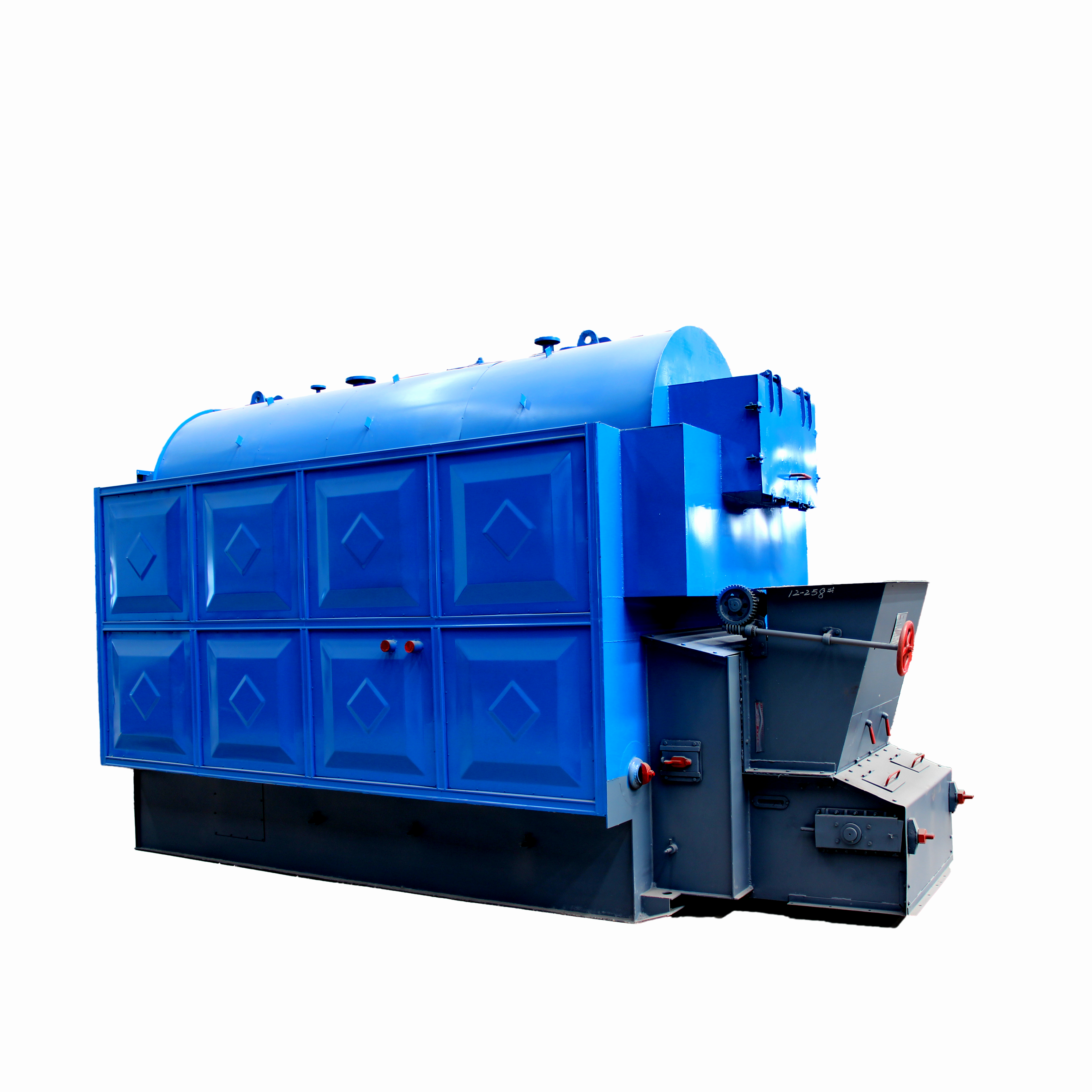

Display

Feature:

1. High thermal efficiency

2. By mechanize operation, reduce intensity of labour of stoker.

3. Easy for installation, when on site, only install slag remover, valve, pipe, water and power, etc., the boiler can be launched into running, additionally, the firing is fast.

4. Easy for installation and moving, save a great amount of capital outlay.

5. Fule: Biomass, coal, wood, rice husk, shells, pellets, bagasse, waste , lower calorific value: 12792KJ/Kg.

Parameter :

DZG(L)Bearing Pressure Hot water boiler

Main Technology Parameter List

| Model | DZG0.7-0.7/95/70 DZL0.7-0.7/95/70 |

DZG1.4-0.7/95/70 DZL1.4-0.7/95/70 DZL1.4-1.0/115/70 |

DZL28-1.0/115/70 DZL2.8-1.25/130/70 |

DZL4.2-1.0/115/70 DZL4.2-1.25/130/70 |

|

| Rated Capacity T/h | 0.7 | 1.4 | 2.8 | 4.2 | |

| Rated Working Pressure Mpa | 0.7 | 0.7/1.0 | 1.0/1.25 | 1.0/1.25 | |

| Rated Steam Temp. ℃ | 95 | 95/115 | 115/130 | 115/130 | |

| Feed Water Temp. ℃ | 70 | 70 | 70 | 70 | |

| Fuel Consumption Kg/H | ~150 | ~310 | ~590 | ~900 | |

| Thermal Efficiency % | 75 | 78 | 79 | 77.44 | |

| Heating Surface | Boiler Body m² | 32.4 | 33.85 | 75.75 | 142 |

| Economizer m² | 24.64 | 38.5 | 87.2 | ||

| Grate area m² | 1.4/2.05 | 2.3/3.5 | 4.66 | 7.4 | |

| Designed Fuel Type | Biomass | Biomass | Biomass | Biomass | |

| Max. Transport Weight T | ~16 | ~21 | ~26.5 | ~30 | |

| Max. Transport Dimension m | 4.3×2.25×2.955.26×2.25×2.95 | 5.1×2.2×3.35.9×2.2×3.3 | 6.5×2.6×3.5 | 6.01×3.4×3.57.29×2.9×1.7 | |

| Model | DZL7-1.0/115/70 | DZL14-1.0/115/70 | DZL29-1.25/130/70 | DZL46-1.25/130/70 | DZL58-1.25/130/70 | DZL70-1.25/130/70 |

| Rated Capacity T/h | 7 | 14 | 29 | 46 | 58 | 70 |

| Rated Working Pressure Mpa | 1.0 | 1.0 | 1.25 | 1.25 | 1.25 | 1.25 |

| Rated Steam Temp. ℃ | 115 | 115 | 130 | 130 | 130 | 130 |

| Feed Water Temp. ℃ | 70 | 70 | 70 | 70 | 70 | 70 |

| Heating AreaBoiler Body m² | 228.6 | 434.7 | Radiation:73.07Convection:903.01 | Radiation:147.8Convection:1418.5 | Radiation:147.8Convection:1418.5 | Radiation:147.8Convection:1418.5 |

| Grate area m² | 11.5 | 22.5 | 34.5 | 57.8 | 77 | 91 |

| Fuel Consumption Kg/h | ~1440 | ~2700 | ~6610 | ~10500 | ~12800 | ~15300 |

| Thermal Efficiency % | 80 | 80 | 82.5 | 82.05 | 83.03 | 83.28 |

| Max. Transport Weight Ton | 35 | 28 | 19.68 | 28.796 | 31 | 31 |

Note: Parameter is just for reference, the exact parameter should follow the factory technical data.

Product detail pictures:

Related Product Guide:

Boiler Structure

Our purpose would be to offer good quality products at competitive price ranges, and top-notch support to clients around the whole world. We're ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for China Biomass Steam Boiler Manufacturers - Biomass Hot Water Boiler – Double Rings , The product will supply to all over the world, such as: Jeddah, Bulgaria, Indonesia, Aiming to grow to be by far the most experienced supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal merchandise. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. In depth data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're about to make it possible for you to get complete acknowledge about our things and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!