Thermal Oil Boiler China - Installation & Technology Service – Double Rings

Thermal Oil Boiler China - Installation & Technology Service – Double Rings Detail:

Installation Procedure

Step 1. Slag Extruder put into Foundation|

Step 2. Lift Boiler Body to Foundation . Then install the Platform and Stair.

Step 3.Connect Boiler,Economizer (Down Part) and Gas Flue.

Step 4. Connect Economizer ( Up Parts) and Gas Flue.

Step 5.Use asbest rope to Fix Economizer and Gas Flue. Keep no gas leak.

Step 6. Lift Dust Cleaner to Foundation.

Step 7.Connect and fix the Gas Flue between Dust Cleaner and Economizer .

Step 8. Lift I.D Fan to Foundation

Step 9. Connect and fix the Gas Flue between Dust Cleaner and I.D Fan .

Step 10. Lift and Install Chimney , Connect I.D Fan with Chimney.

Step 11. Install F.D Fan

Step 12. Install Coal Feeder

Step 13. Install Reducer

Step 14. Install Valve&Gauge in Boiler Body

Install Valve&Gauge of Economizer

Step 15. Install Steam Distribution Cylinder,connect Main Steam Pipe and Valve&Gauge.

Customer arrange Steam Pipe Route according to the real situation in their factory.

Step 16. Install Water Pump and Valve&Gauge

Customer arrange Water Pipe Route according to the real situation in their factory.

Vertical Style Stainless Steel Water Pump need Vertically Installation.

Step 17. Install the Light,Motor Electric Wire and Electric Control Cabinet

Customer arrange Electric Wire Route according to the real situation in their factory.

Step 18. Install Water Treatment

All Boiler Installation Finish

Note: This Procedure was recommended by Double Rings. Real Operation is according to local situation and Manual. Photos in the paper is just to display.Real Equipments are subject to actual receipt cargo.

Service after Sale

| Service after Sale: | |

| Warrant Time | One Year for Whole Boiler without mistake operation after shipment. |

| Technology Service | For life.Customer has any questions about the boiler, our engineers will serve and supply the Technology Service immediately. |

| Guidance Installation | After finish the foundation and boiler arrived in the customer’s factory,two engineers will go to customer’s factory to guidance installation with local workers . |

| Commissioning | After installed, the boiler will be commissioning and training for 2days. |

| Charge | The buyer should provide air tickets with round trip, accommodation, food and local communication and transportation for the engineers, plus the subsidy for each engineer. |

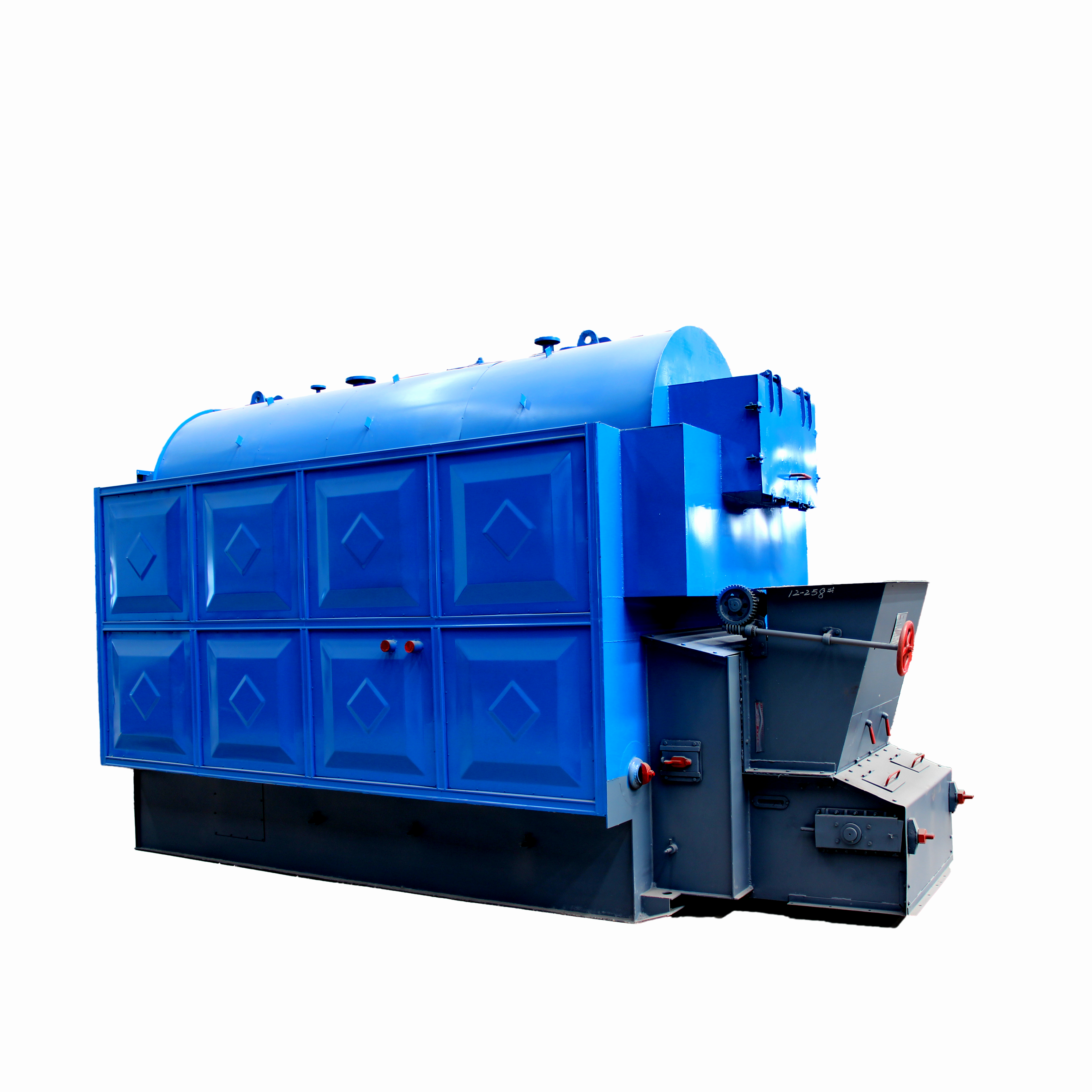

Product detail pictures:

Related Product Guide:

Boiler Structure

We offer fantastic energy in high quality and enhancement,merchandising,profits and promoting and procedure for Thermal Oil Boiler China - Installation & Technology Service – Double Rings , The product will supply to all over the world, such as: Casablanca, Romania, India, With a fully integrated operation system, our company has won a good fame for our high quality goods, reasonable prices and good services. Meanwhile, we have established a strict quality management system conducted in material incoming, processing and delivery. Abiding by the principle of "Credit first and customer supremacy", we sincerely welcome clients from home and abroad to cooperate with us and advance together to create a brilliant future.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.