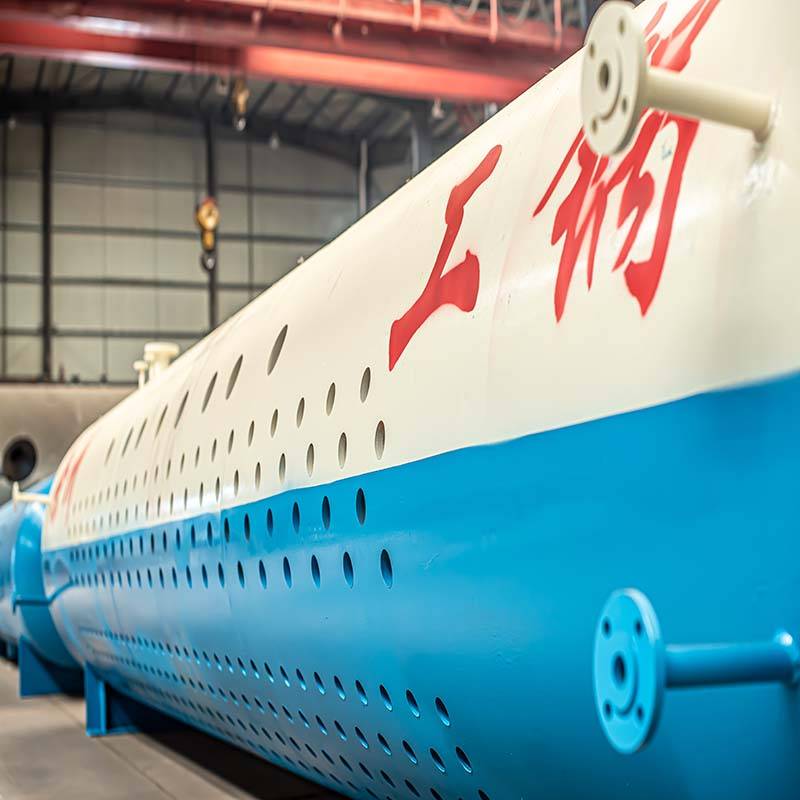

Thermal Oil Boiler - LPG Pressure Tank – Double Rings

Thermal Oil Boiler - LPG Pressure Tank – Double Rings Detail:

Introduction:

Pressure vessel equipment plays an important role in the petrochemical industry, the energy industry, scientific research and military sectors etc.

Pressure vessel container body consist of cylinder, sealing head, flange, sealing elements, open pore and connected pipe, bearing.

In addition, also equipped with safety devices, meter and safety internals for protection purpose .

Pressure Vessel Main Performance Parameter List

Steam Pressure1.0Mpa

Inlet Temperature 250℃

Saturation Temperature 179℃

Heating Water:Inlet Temperature 90℃;

Outlet Temperature 140℃

Product detail pictures:

Related Product Guide:

Boiler Structure

We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for Thermal Oil Boiler - LPG Pressure Tank – Double Rings , The product will supply to all over the world, such as: Sierra Leone, Hungary, Libya, What is good price? We provide customers with factory price. In the premise of good quality, efficiency must be paid attention to and maintain appropriate low and healthy profits. What is a fast delivery? We make the delivery according to customers' requirements. Although delivery time depends on the order quantity and the complexity of it, we still try to supply products in time. Sincerely hope we could have long term business relationship.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.

Write your message here and send it to us