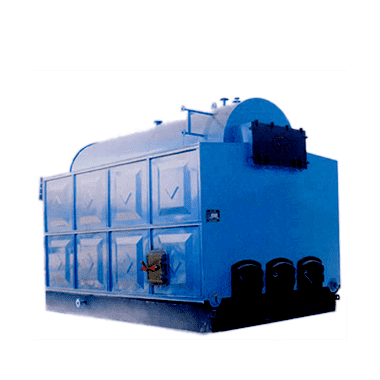

professional factory for Boiler Installation Material – Wood Biomass Boiler – Double Rings

professional factory for Boiler Installation Material – Wood Biomass Boiler – Double Rings Detail:

Korean Purchased two sets Biomass Boiler

Type: DZL 4-1.25-S ; SZL 10-1.25-S ;

Fuel : Wood Chip, Wood ,Plywood chip etc.

Usage : Plywood Factory

Product detail pictures:

Related Product Guide:

Boiler Structure

Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction for professional factory for Boiler Installation Material – Wood Biomass Boiler – Double Rings , The product will supply to all over the world, such as: South Korea, Seychelles, Peru, We are very responsible for all details on our customers order no matter on warranty quality, satisfied prices, quick delivery, on time communication, satisfied packing, easy payment terms, best shipment terms, after sales service etc. We provide one-stop service and best reliability to our every customers. We work hard with our customers, colleagues, workers to make a better future.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!

Write your message here and send it to us