Professional Design Fire Tube Boilers - Autoclave and Boiler – Double Rings

Professional Design Fire Tube Boilers - Autoclave and Boiler – Double Rings Detail:

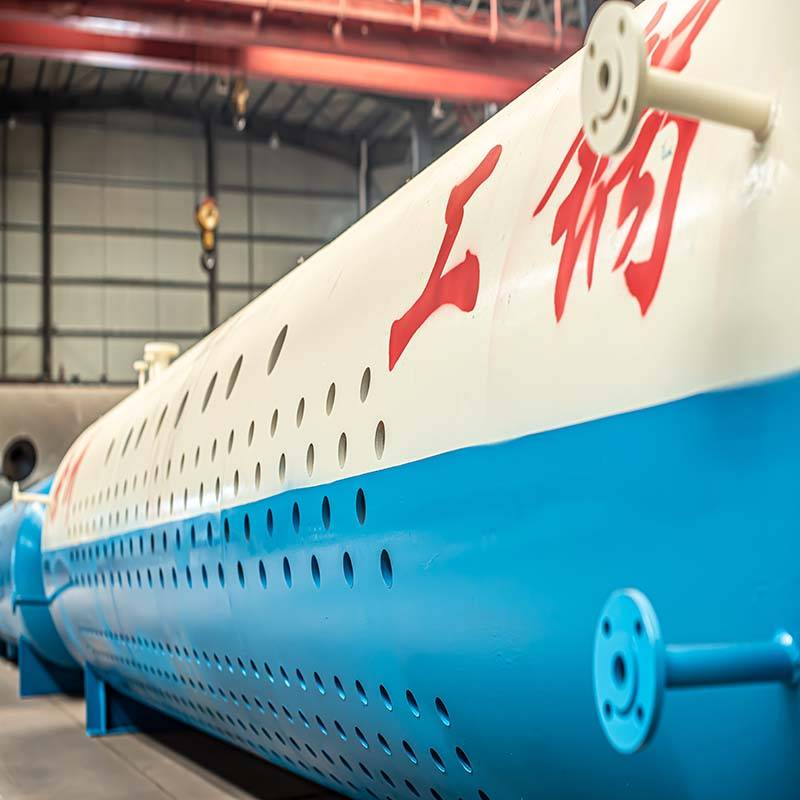

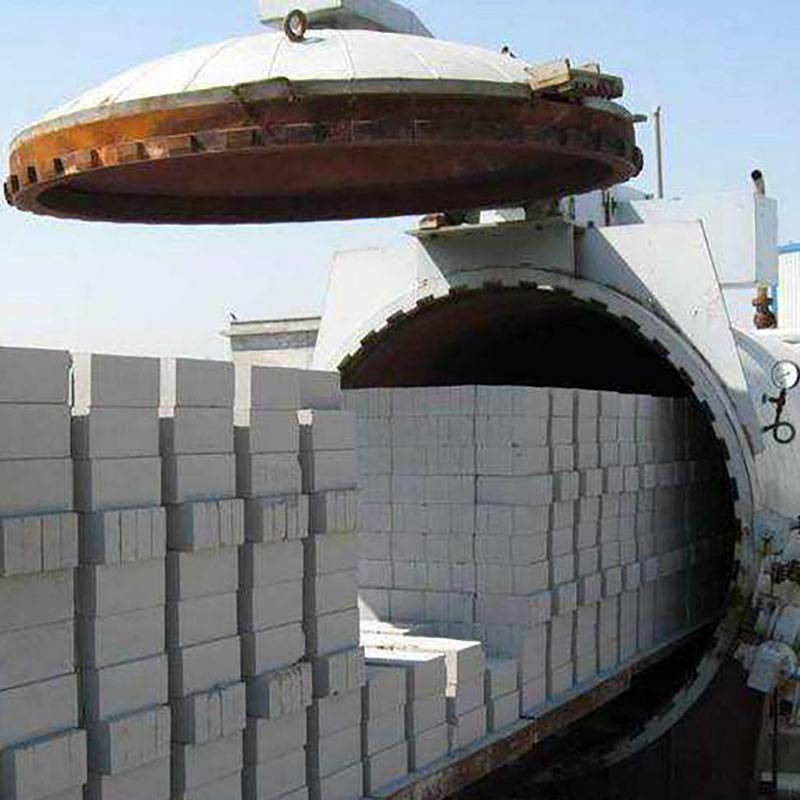

Autoclave-Popular used in ACC Plant,Flyash Plant,Building Material etc..

Autoclave Feature

1, the first domestic production of autoclave professional factory.

2, assembly line production, welding all the automation, quality and stability.

3, all the pressure components 100% X-ray film detection, advanced detection methods.

4, the product as a whole factory, advanced and reasonable structure, short installation period, the investment cost is low.

5, fully furnished, by manual or computer control.

Autoclave use:

Autoclave steam curing equipment for large, can be used for steam-cured sand lime bricks, fly ash bricks, aerated concrete blocks, high-strength concrete pole, pipe and other concrete products, but also for timber, medicine, chemical industry, glass, insulation materials and other industries.

Autoclave Specification

Autoclave Series

Main Technology Parameter List

| ModelItem | FGZCS1.0-1.65×21 | FGZCS1.3-2×21 | FGZCS1.3-2×22 | FGZCS1.3-2×26 | FGZCS1.3-2×27.5 | FGZCS1.3-2x30 |

| Inside Diameter mm |

1650 |

2000 |

2000 |

2000 |

2000 |

2000 |

| Effective Length mm |

21000 |

21000 |

22000 |

26000 |

27500 | 30000 |

| Design Pressure Mpa |

1.08 |

1.4 |

1.4 |

1.4 |

1.4 |

1.4 |

| Design Temperature ℃ |

187 |

197.3 |

197.3 |

197.3 |

197.3 |

197.3 |

| Working Pressure Mpa |

1.0 |

1.3 |

1.3 |

1.3 |

1.3 |

1.3 |

| Working Temperature ℃ |

183 |

193.3 |

193.3 |

193.3 |

193.3 |

193.3 |

| Actuating Medium |

Saturated Steam , condensed water |

|||||

| Inside Rail Distance mm |

600 |

448 |

600 |

750 |

600 |

600 |

| Effective Volume m3 |

46 |

68 |

71 |

84 |

88.5 |

96.4 |

| Gross Weight Kg |

18830 |

25830 |

26658 |

30850 |

32170 |

34100 |

| Overall Dimension mm |

21966x 2600×2803 |

22300x 2850×3340 |

23300x2850x3340 |

27300x 2850×3340 |

28800x 2850×3340 |

31300x 2850×3340 |

| ModelItem | FGZCS1.5-2.68×22.5 | FGZCS1.5-2.68×26 | FGZCS1.5-2.68x39 | FGZCS1.5-2.85×21 | FGZCS1.5-2.85×23 | |

| Inside Diameter mm |

2680 |

2680 |

2680 |

2850 |

2850 |

|

| Effective Length mm |

22500 |

26000 |

39000 |

21000 |

23000 | |

| Design Pressure Mpa |

1.6 |

1.6 |

1.6 |

1.6 |

1.6 |

|

| Design Temperature ℃ |

204 |

204 |

204 |

201.3 |

203 |

|

| Working Pressure Mpa |

1.5 |

1.5 |

1.5 |

1.5 |

1.5 |

|

| Working Temperature ℃ |

200 |

200 |

200 |

197.3 |

199 |

|

| Actuating Medium |

Saturated Steam , condensed water |

|||||

| Inside Rail Distance mm |

800 |

800 |

800 |

1000 |

963 |

|

| Effective Volume m3 |

134 |

154.2 |

227.5 |

137 |

150 |

|

| Gross Weight Kg |

45140 |

46700 |

67480 |

45140 |

44565 |

|

| Overall Dimension mm |

24180x 3850×4268 |

27650x 3454×4268 |

40650x3454x4268 |

22634x 3462×4495 |

24900x 3490×4500 |

|

| ModelItem | FGZCS1.5-2.85×24 | FGZCS1.5-2.85×25 | FGZCS1.5-2.85x26 | FGZCS1.5-2.85x26.5 | FGZCS1.5-2.85x27 | |

| Inside Diameter mm |

2850 |

2850 |

2850 |

2850 |

2850 |

|

| Effective Length mm |

24000 |

25000 |

26000 |

26500 |

27000 | |

| Design Pressure Mpa |

1.6 |

|||||

| Design Temperature ℃ |

203 |

|||||

| Working Pressure Mpa |

1.5 |

|||||

| Working Temperature ℃ |

199 |

|||||

| Actuating Medium |

Saturated Steam , condensed water |

|||||

| Inside Rail Distance mm |

963 |

849 |

963 |

900 |

915 |

|

| Effective Volume m3 |

150 |

161 |

170 |

173 |

180 |

|

| Gross Weight Kg |

46035 |

48030 |

54530 |

54880 |

55600 |

|

| Overall Dimension mm |

25900x 3490×4500 |

26640x 3640×4495 |

27634x3640x4495 |

28134x 3462×4495 |

28640x 3640×4495 |

|

| ModelItem | FGZCS1.5-2.85×29 | FGZCS1.5-2.85×36 | FGZCS1.5-3x23 | FGZCS1.5-3x31 | FGZCS1.5-3.2x24.5 | |

| Inside Diameter mm |

2850 |

2850 |

3000 |

3000 |

3200 |

|

| Effective Length mm |

29000 |

36000 |

23000 |

31000 | 32000 | |

| Design Pressure Mpa |

1.6 |

|||||

| Design Temperature ℃ |

203 |

|||||

| Working Pressure Mpa |

1.5 |

|||||

| Working Temperature ℃ |

199 |

|||||

| Actuating Medium |

Saturated Steam , condensed water |

|||||

| Inside Rail Distance mm |

963 |

900 |

1220 |

1000 |

1200 |

|

| Effective Volume m3 |

190 |

234 |

167 |

227 |

206 |

|

| Gross Weight Kg | 58400 |

70020 |

56765 |

70410 |

62440 | |

| Overall Dimension mm | 30634x3640x4495 | 37634x3462x4495 | 24875x3516x4804 | 32875x3516x4804 | 26570x3750x5027 | |

Product detail pictures:

Related Product Guide:

Boiler Structure

We always think and practice corresponding to the change of circumstance, and grow up. We purpose at the achievement of a richer mind and body as well as the living for Professional Design Fire Tube Boilers - Autoclave and Boiler – Double Rings , The product will supply to all over the world, such as: Mecca, Mombasa, Cannes, We are sticking to excellent quality, competitive price and punctual delivery and better service, and sincerely hope to establish long-term good relationships and cooperation with our new and old business partners from all over the world. Sincerely welcome you to join us.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly