OEM/ODM Manufacturer Condensing Gas Boilers - SZS Gas Oil PLG Boiler – Double Rings

OEM/ODM Manufacturer Condensing Gas Boilers - SZS Gas Oil PLG Boiler – Double Rings Detail:

Introduction :

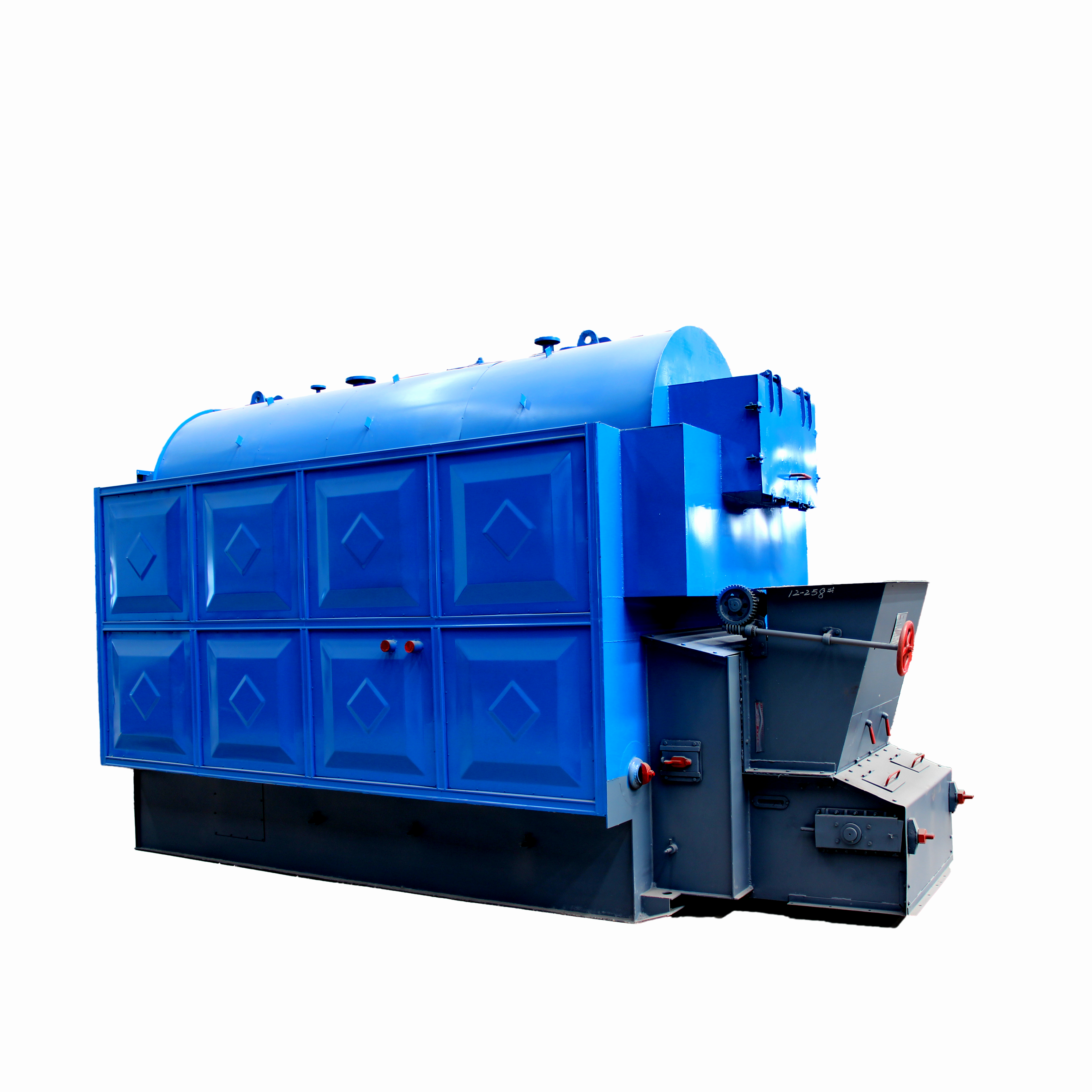

SZS series boiler body is longitudinal 2-drum, D-type chamber combustion strueture. The furnace is on right side and the convection bank tube is on left side. The body is fixed on the body chassis by flexible supports in the middle and two ends of the lower drum,can secure to let the whole boiler body to expand sideways. Surround furnace there are narrow space membrane cooling tube wall. It is totally sealed and separated between the membrane wall on furnace left side and the convection bank tube. The rear part of convection tube bank is a tube-reducing staggered structure,

and the front part is aligned structure. The flue gas generated from furnace combustion flows from furnace rear outlet to the end of combustion chamber, convection tube bank area, amt then turns from the front-left of furnace to the spiral finned tube energy saver, and finally flows into ducting and through chimney emits to atmosphere.

Feature:

1. Due to combustion chamber applying whole membrane water cooling structure.and adopted micro–positive pressure combustion, there is no smoke leakage, and there is no pollution in operation environment;

2. There are explosion door and flame sensor in the boiler arrangement and so operation is safe and reliable;

3. At boiler rear, it adopts the spiral finned tube type energy saver that reduces flue gas emission temperature and therefore raises thermal efficiency. The design efficiency is above 92%;

4.The boiler is horizontal arrangement in compact structure with small floor space area;

5.The manholes are arranged at the two ends of upper and lower drums, and check door is set a rear part of boiler. These openings make users easy for entering inside doing maintenance and cleaning work;

6. The boiler is wholly assembled for delivery, easy for transportation and shortened for installation period;

7.The boiler achieves fully automatic control. It has the functions of automatic running and protection with easy operation.

Product detail pictures:

Related Product Guide:

Boiler Structure

Using a full scientific good quality administration system, very good quality and superior faith, we win good standing and occupied this discipline for OEM/ODM Manufacturer Condensing Gas Boilers - SZS Gas Oil PLG Boiler – Double Rings , The product will supply to all over the world, such as: Victoria, French, Georgia, We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we provide shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we've got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.