OEM Supply Oil Burning Boiler - Biomass Hot Water Boiler – Double Rings

OEM Supply Oil Burning Boiler - Biomass Hot Water Boiler – Double Rings Detail:

Introduction :

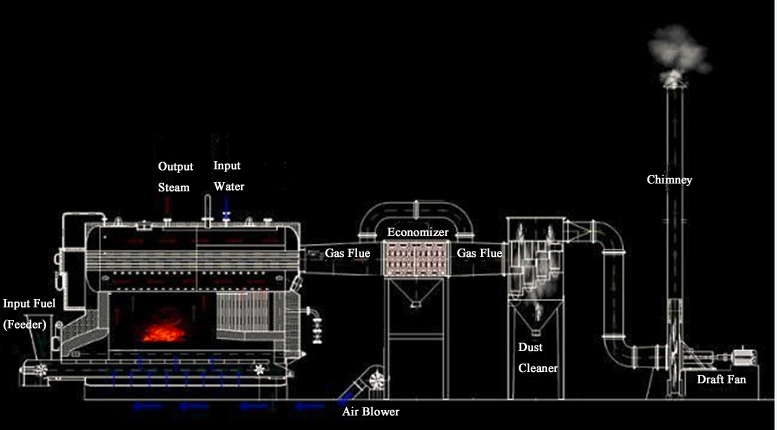

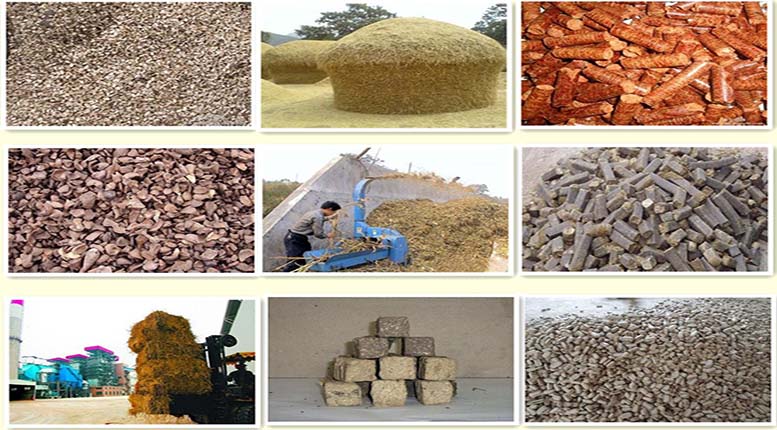

Biomass boiler is horizontal three-back water fire pipe composite boiler. The fuel can be Biomass,coal,wood,rice husk,shells,pellets,bagasse,waste etc..

Display

Feature:

1. High thermal efficiency

2. By mechanize operation, reduce intensity of labour of stoker.

3. Easy for installation, when on site, only install slag remover, valve, pipe, water and power, etc., the boiler can be launched into running, additionally, the firing is fast.

4. Easy for installation and moving, save a great amount of capital outlay.

5. Fule: Biomass, coal, wood, rice husk, shells, pellets, bagasse, waste , lower calorific value: 12792KJ/Kg.

Parameter :

DZG(L)Bearing Pressure Hot water boiler

Main Technology Parameter List

| Model | DZG0.7-0.7/95/70 DZL0.7-0.7/95/70 |

DZG1.4-0.7/95/70 DZL1.4-0.7/95/70 DZL1.4-1.0/115/70 |

DZL28-1.0/115/70 DZL2.8-1.25/130/70 |

DZL4.2-1.0/115/70 DZL4.2-1.25/130/70 |

|

| Rated Capacity T/h | 0.7 | 1.4 | 2.8 | 4.2 | |

| Rated Working Pressure Mpa | 0.7 | 0.7/1.0 | 1.0/1.25 | 1.0/1.25 | |

| Rated Steam Temp. ℃ | 95 | 95/115 | 115/130 | 115/130 | |

| Feed Water Temp. ℃ | 70 | 70 | 70 | 70 | |

| Fuel Consumption Kg/H | ~150 | ~310 | ~590 | ~900 | |

| Thermal Efficiency % | 75 | 78 | 79 | 77.44 | |

| Heating Surface | Boiler Body m² | 32.4 | 33.85 | 75.75 | 142 |

| Economizer m² | 24.64 | 38.5 | 87.2 | ||

| Grate area m² | 1.4/2.05 | 2.3/3.5 | 4.66 | 7.4 | |

| Designed Fuel Type | Biomass | Biomass | Biomass | Biomass | |

| Max. Transport Weight T | ~16 | ~21 | ~26.5 | ~30 | |

| Max. Transport Dimension m | 4.3×2.25×2.955.26×2.25×2.95 | 5.1×2.2×3.35.9×2.2×3.3 | 6.5×2.6×3.5 | 6.01×3.4×3.57.29×2.9×1.7 | |

| Model | DZL7-1.0/115/70 | DZL14-1.0/115/70 | DZL29-1.25/130/70 | DZL46-1.25/130/70 | DZL58-1.25/130/70 | DZL70-1.25/130/70 |

| Rated Capacity T/h | 7 | 14 | 29 | 46 | 58 | 70 |

| Rated Working Pressure Mpa | 1.0 | 1.0 | 1.25 | 1.25 | 1.25 | 1.25 |

| Rated Steam Temp. ℃ | 115 | 115 | 130 | 130 | 130 | 130 |

| Feed Water Temp. ℃ | 70 | 70 | 70 | 70 | 70 | 70 |

| Heating AreaBoiler Body m² | 228.6 | 434.7 | Radiation:73.07Convection:903.01 | Radiation:147.8Convection:1418.5 | Radiation:147.8Convection:1418.5 | Radiation:147.8Convection:1418.5 |

| Grate area m² | 11.5 | 22.5 | 34.5 | 57.8 | 77 | 91 |

| Fuel Consumption Kg/h | ~1440 | ~2700 | ~6610 | ~10500 | ~12800 | ~15300 |

| Thermal Efficiency % | 80 | 80 | 82.5 | 82.05 | 83.03 | 83.28 |

| Max. Transport Weight Ton | 35 | 28 | 19.68 | 28.796 | 31 | 31 |

Note: Parameter is just for reference, the exact parameter should follow the factory technical data.

Product detail pictures:

Related Product Guide:

Boiler Structure

We emphasize progress and introduce new solutions into the market each year for OEM Supply Oil Burning Boiler - Biomass Hot Water Boiler – Double Rings , The product will supply to all over the world, such as: Jakarta, Mexico, Saudi Arabia, We also have the strong ability of integration to supply our best service, and plan to build the warehouse in the different countries around the world, that will be more conveniently to service our customers.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.