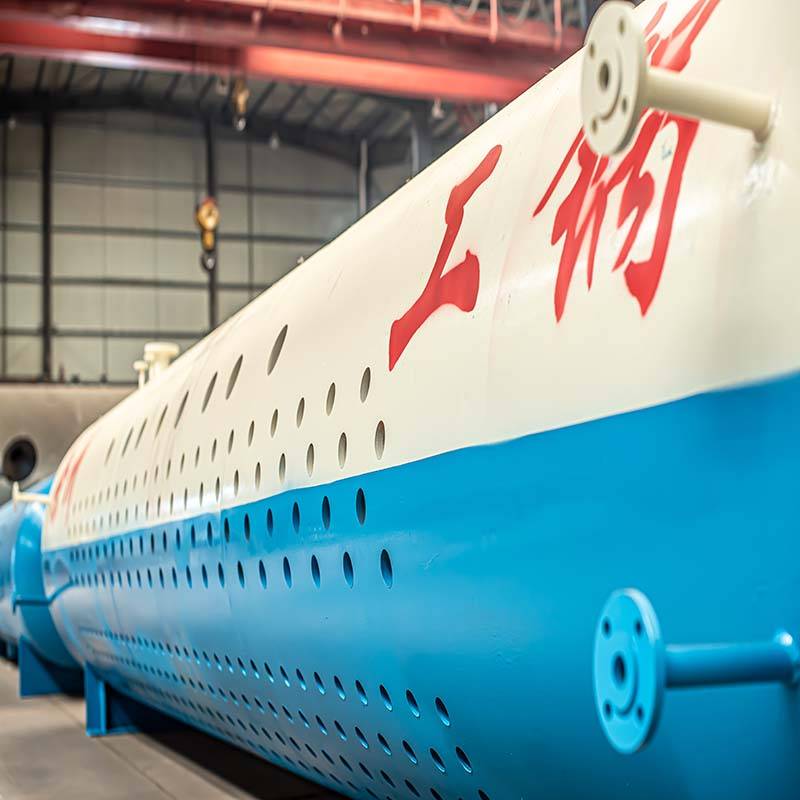

OEM Supply Diesel Steam Boiler - Boiler Tube – Double Rings

OEM Supply Diesel Steam Boiler - Boiler Tube – Double Rings Detail:

More Photos

Boiler Steel Pipe/Tube is a kind of seamless steel pipe. The manufacturing method is the same as seamless steel pipes, but there are strict requirements for the steel grades used to manufacture boiler steel pipes. According to the temperature level, it is divided into two types: low pressure boiler tube and high pressure boiler tube.

Product detail pictures:

Related Product Guide:

Boiler Structure

We not only will try our greatest to offer you excellent services to just about every client, but also are ready to receive any suggestion offered by our buyers for OEM Supply Diesel Steam Boiler - Boiler Tube – Double Rings , The product will supply to all over the world, such as: Borussia Dortmund, Egypt, Monaco, Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to supply our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We have been ready to face the worries and make the improve to understand all the possibilities in international trade.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.

Write your message here and send it to us