OEM China Boiler Installation Material - Gas/Oil Fired Hot Water Boiler – Double Rings

OEM China Boiler Installation Material - Gas/Oil Fired Hot Water Boiler – Double Rings Detail:

Introduction :

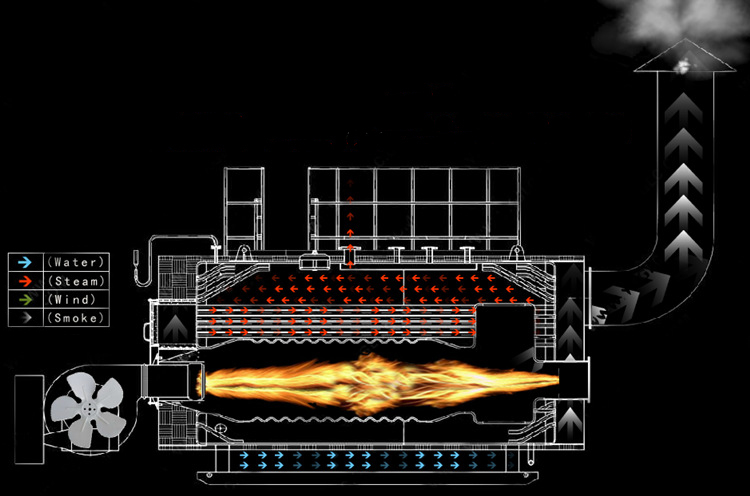

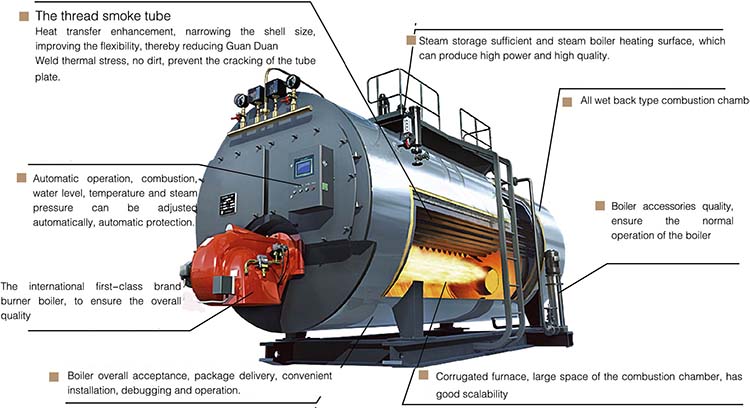

WNS series steam boiler burning oil or gas is Horizontal internal combustion three backhaul fire tube boiler, adopts boiler furnace wet back structure, high temperature smoke, gas turn to scour the second and third backhaul smoke tube plate, then after the smoke chamber. discharged into the atmosphere through the chimney.

There are the front and back Smokebox Cap in the boiler, easy to maintenance.

Excellent burner adopts combustion automatic ratio adjustment , feedwater automatic control, start and stop program , automatic operation and other advanced technology, also has the High&Low water level alarm and protection function of Extreme low water levels, ultra-high pressure, turn off etc..

The boiler has the features of compact structure, safe and reliable, simple operation, quick installation, less pollution, low noise, and high efficiency.

Feature:

1.Overall structure is reasonable and compact, easy to install.

The boiler is composed of Boiler body, chimney and piping system. The boiler body and chimney have been finished in the factory, the pipe, valve and gauge in the boiler have also been completed in the factory. The clients only need to assemble the boiler and chimney together , connect the gas ,power, water and then

to test run , greatly shorten the installation time, and ensure the quality of the boiler.

2. Advanced design, the whole structure, combustion chamber assemble in Front smokebox cover, the body has the heating surface and combustion chamber. It is the reasonable structure, compact, low consumption of steel , the furnace gall is bias wave form furnace, the insulation layer is new thermal insulation materials, color sheet packaging, packaging shape is rectangular, the boiler performance, weight, structure, size, shape modeling is more advanced and perception .

The feed water device equip on the right side of the boiler base , the whole structure, do not need another foundation.

3. Simple water cycle, reasonable structure of pressure parts, guarantee water quality, safe to run

4. Complete Ancillary equipment, advanced comprehensive technology

Parameter

WNS Hot Water Boiler burning oil or gas

Main Technology Parameter List

| ModelItem | WNS0.35-0.7/95/70-YQ | WNS0.7-0.7/90/70-YQ | WNS1.05-0.7/95/70-YQ | WNS1.4-0.7/95/70-YQ | WNS2.1-0.7/95/70-YQ | |

| Rated Capacity Mw |

0.35 |

0.7 |

1.05 |

1.4 |

2.1 |

|

| Rated Working Pressure |

0.7 Mpa |

0.7 Mpa |

0.7 Mpa |

0.7 Mpa |

0.7 Mpa | |

| Output Water Temp. ℃ |

95 |

95 |

95 |

95 |

95 |

|

| Return Water Temp. ℃ |

70 |

|||||

| Heating Surface m² |

12.05 |

30.7 |

45.5 |

60.9 |

90.5 |

|

| Exhaust gas Temp. ℃ |

180 |

180 |

178 |

181 |

179 |

|

| Thermal Efficiency % |

84 |

85 |

86 |

88 |

88 |

|

| Design Fuel |

Diesel Oil/Heavy Oil/Natural Gas/Liquid Gas/Town Gas |

|||||

| Ringelmann shade |

< Grade 1 |

|||||

| FuelConsumption

Kg/h (Nm3/h) |

Diesel Oil |

31 |

62.5 |

93.66 |

124.75 |

187.11 |

| Heavy oil |

33.5 |

66.99 |

98.89 |

131.72 |

197.55 |

|

| Liquid gas |

36 |

72.2 |

108.23 |

144.16 |

216.21 |

|

| Town gas |

74 |

144 |

216.5 |

288.3 |

432.4 |

|

| Boiler Weight Ton | Empty |

2.562 |

4.95 |

5.5 |

7.34 |

10.1 |

| Full Water |

3.162 |

6.5 |

7.6 |

12.8 |

16 |

|

| Power Source V | 380V/50Hz | |||||

| ModelItem | WNS2.8-1.0/115/70WNS2.8-1.25/130/70 | WNS3.5-1.0/115/70WNS3.5-1.25/130/70 | WNS4.2-1/115/70 WNS4.2-1.25/130/70 | WNS5.6-1/115/70WNS5.6-1.25/130/70 | WNS7-1/115/70WNS7-1.25/130/70 | |

| Rated Capacity Mw |

2.8 |

3.5 |

4.2 |

5.6 |

7 |

|

| Rated Working Pressure | 1.0/1.25 Mpa |

1.0/1.25 Mpa |

1.0/1.25 Mpa |

1.0/1.25 Mpa |

1.0/1.25 Mpa | |

| Output Water Temp. ℃ |

115/130 |

115/130 |

115/130 |

115/130 |

115/130 |

|

| Return Water Temp. ℃ |

70 |

|||||

| Heating Surface m² |

124.7 |

137 |

145 |

165 |

210 |

|

| Exhaust gas Temp. ℃ |

180.5 |

180 |

179 |

178.5 |

182 |

|

| Thermal Efficiency % |

88 |

89 |

89 |

90 |

90 |

|

| Design Fuel |

Diesel Oil/Heavy Oil/Natural Gas/Liquid Gas/Town Gas |

|||||

| Ringelmann shade |

< Grade 1 |

|||||

| FuelConsumption

Kg/h (Nm3/h) |

Diesel Oil |

249.21 |

311.17 |

373.41 |

497.78 |

621 |

| Heavy oil |

263.12 |

328.55 |

394.26 |

525.57 |

680 |

|

| Liquid gas |

287.98 |

359.58 |

431.5 |

575.2 |

719.17 |

|

| Town gas |

575.96 |

719.16 |

863 |

1151 |

1438 |

|

| Boiler Weight Ton | Empty |

13.9 |

14.5 |

15.1 |

19.1 |

19.7 |

| Full Water |

22.5 |

24.9 |

25.5 |

31.8 |

37 |

|

| Power Source V | 380V/50Hz | |||||

Product detail pictures:

Related Product Guide:

Boiler Structure

Bear "Customer initially, High quality first" in mind, we do the job closely with our customers and supply them with efficient and skilled providers for OEM China Boiler Installation Material - Gas/Oil Fired Hot Water Boiler – Double Rings , The product will supply to all over the world, such as: Swedish, Vancouver, Salt Lake City, Meanwhile, we're building up and consummating triangle market & strategic cooperation in order to achieve a multi-win trade supply chain to expand our market vertically and horizontally for a brighter prospects. development. Our philosophy is to create cost-effective products, promote perfect services, cooperate for long-term and mutual benefits, firm a comprehensive mode of excellent suppliers system and marketing agents, brand strategic cooperation sales system.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.