Leading Manufacturer for Bosch Boiler - Vertical Gas Oil Boiler – Double Rings

Leading Manufacturer for Bosch Boiler - Vertical Gas Oil Boiler – Double Rings Detail:

Introduction :

1. Compact structure, small installation area, easy to install.

2. Good heating surface , low exhaust gas temperature

3. The world famous original burner, automatic and high efficient combustion, high combustion efficiency

4. Microcomputer automatic controller, overpressure protection and ultra-low water level automatic protection and automatic feed water .

5. Super thickness insulating layer design, good insulation effect, boiler surface temperature low, low losing heating.

6. Small dust emission to achieve the requirements of the national environmental safety.

Steam Boiler Parameter

LHS Vertical Steam Boiler burning oil or gas

Main Technology Parameter List

| ModelItem | LHS0.1-0.4-YQLHS0.1-0.7-YQ | LHS0.2-0.4-YQLHS0.2-0.7-YQ | LHS0.3-0.4-YQLHS0.3-0.7-YQ | LHS0.5-0.4-YQLHS0.5-0.7-YQ | LHS0.7-0.4-YQLHS0.7-0.7-YQ | LHS1-0.4-YQLHS1-0.7-YQLHS1-1.0-YQ |

| Rated Capacity T/h |

0.1 |

0.2 |

0.3 |

0.5 |

0.7 |

1.0 |

| Rated Working Pressure |

0.4/0.7 Mpa |

0.4/0.7 Mpa |

0.4/0.7 Mpa |

0.4/0.7 Mpa |

0.4/0.7 Mpa |

0.4/0.7 Mpa |

| Rated Steam Temp. ℃ |

152/170 |

151.8/170 |

151.8/170 |

151.8/170 |

151.8/170 |

151.8/170/183 |

| Feed Water Temp. ℃ |

20 |

|||||

| Heating Surface m² |

2.3 |

4.34 |

6.53 |

12.05 |

20.93 |

25.48 |

| Installed Overall Dimension |

1.26×1.25×1.97 |

1.456×1.35×2.07 |

1.91×1.68×2.475 |

2.15×1.9×2.735 |

1.54×2.3×2.855 |

2.963×2.35×3.07 |

| Boiler Weight Ton |

1 |

1.15 |

1.67 |

2.57 |

2.96 |

4.03 |

| Water Pump Model |

JGGC 0.6-8 |

JGGC 0.6-8 |

JGGC 0.6-8 |

JGGC 0.6-12 |

JGGC 0.6-12 |

JGGC 2-10 |

| Chimney mm |

Ø 150 |

Ø 150 |

Ø 200 |

Ø 200 |

Ø 300 |

Ø 300 |

| Thermal Efficiency % |

83 |

83 |

83 |

83 |

83 |

83 |

| Design Fuel |

Light Oil/Town Gas/Natural Gas |

|||||

| Burner Brand` |

Italy RIELLO Burner G20S |

|||||

| Ringelmann shade |

< Grade 1 |

|||||

Hot Water Boiler Parameter

Atmospheric Pressure Hot Water Boiler burning gas or oil

Main Parameter List

|

Model Item |

CLHS0.21-95/ 70-Y(Q)

|

CLHS0.35-95/ 70-Y(Q)

|

CLHS0.5-95/ 70-Y(Q)

|

CLHS0.7-95/ 70-Y(Q)

|

CLHS1.05-95/ 70-Y(Q)

|

CLHS1.4-95/ 70-Y(Q)

|

|

Rated Thermal Power MW |

0.21 |

0.35 |

0.5 |

0.7 |

1.05 |

1.4 |

|

Rated Outlet Water Temp. ℃ |

95 |

|||||

|

Rated Return Water Temp. ℃ |

20 |

|||||

|

Design Fuel |

Heavy oil/0# Light Diesel oil/ Natural Gas |

|||||

|

Heating Surface m² |

10.5 |

12.6 |

15 |

16.5 |

22 |

35.6 |

|

Design Thermal efficiency |

83% |

|||||

|

Heating Area m² |

1800 |

3000 |

4300 |

6000 |

9000 |

12000 |

|

Boiler Body Specification mm |

Ø1164×2040 |

Ø1164×2550 |

Ø1264×2550 |

Ø1364×2360 |

Ø1468×2590 |

Ø1568×2830 |

|

Boiler Weight Ton |

1.7 |

1.9 |

2.5 |

3.0 |

3.1 |

3.8 |

|

Dust emission |

< 100 mg/Nm3 |

|||||

|

Ringelmann shade |

< Grade 1 |

|||||

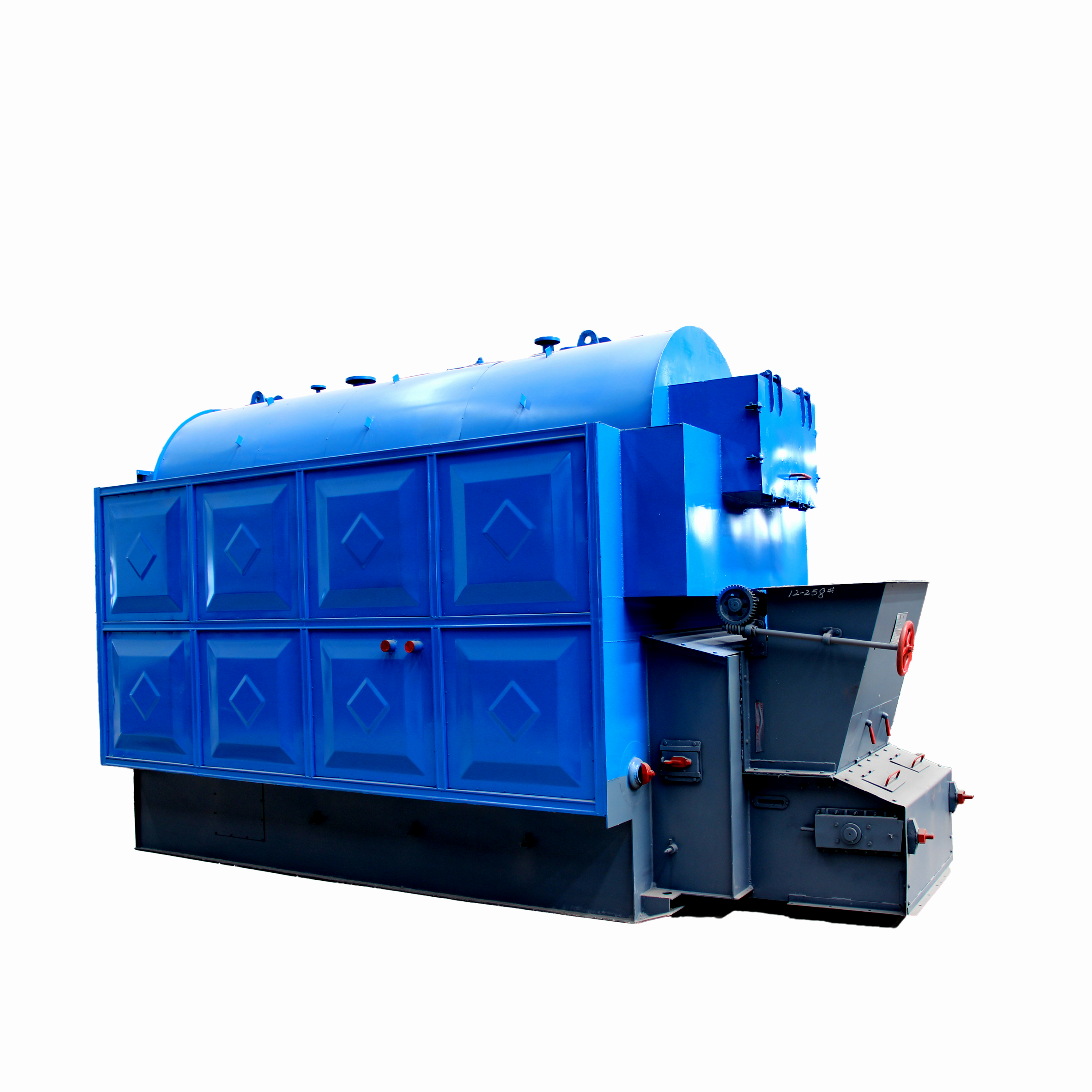

Product detail pictures:

Related Product Guide:

Boiler Structure

We can easily usually fulfill our respected customers with our very good top quality, very good price tag and excellent support due to we have been more expert and much more hard-working and do it in cost-effective way for Leading Manufacturer for Bosch Boiler - Vertical Gas Oil Boiler – Double Rings , The product will supply to all over the world, such as: Yemen, US, Honduras, After years' creating and developing, with the advantages of trained qualified talents and rich marketing experience, outstanding achievements were gradually made. We get good reputation from the customers due to our good solutions quality and fine after-sale service. We sincerely wish to create a more prosperous and flourishing future together with all the friends home and abroad!

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.