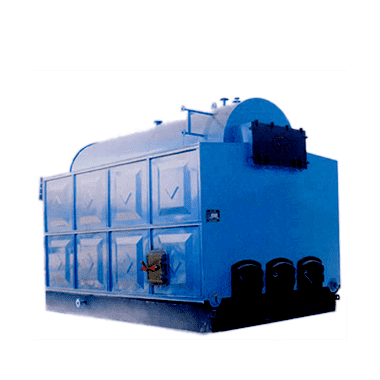

Gas Steam Boiler Factories - Coal Fired Thermal Oil Boiler – Double Rings

Gas Steam Boiler Factories - Coal Fired Thermal Oil Boiler – Double Rings Detail:

Introduction

Thermol Oil boiler uses coal, heavy oil, light oil, combustible gas and other combustible materials as fuel, heat transfer oil as the heat carrier, and uses a circulating oil pump to force a liquid phase to circulate. After the heat energy is transferred to the heating equipment, it is then returned to reheat. Direct current special industrial furnace, heat transfer oil, also known as organic heat carrier or heat medium oil, has been used as an intermediate heat transfer medium in the process of industrial heat exchange for more than 50 years.The principle of the heat-conducting oil furnace is that the furnace is a closed circuit, and the difference between the oil outlet temperature and the oil return temperature is only 20-30 degrees, that is to say, only the temperature difference of 20-30 degrees can reach the operating temperature. The steam boiler adds cold water, which heats the cold water into steam to heat the heating equipment, and the steam becomes 60-70 degree condensed water for discharge. So it plays a role in saving energy and reducing consumption.

Feature:

1. The heating surface adopts close-packed circular coils, and the heating surface is arranged adequately, which reduces the heat load on the surface of the tube, has high thermal efficiency and is safer to use.

2. The fuel burns adiabaticly in the combustion chamber, making it easier to catch fire and burning more fully, which improves the thermal efficiency of the boiler.

3. The medium flow is reasonable, the heat transfer oil has a low inlet to a high outlet, and the gas generated during operation is difficult to retain in the furnace.

4. The furnace roof is arranged with close-packed coils to better protect the furnace roof and avoid the burning of the furnace roof.

5. Easy installation, no foundation is needed, just close the upper body and the lower grate, and the installation period is short ,

Product detail pictures:

Related Product Guide:

Boiler Structure

Being supported by an highly developed and specialist IT team, we could give technical support on pre-sales & after-sales service for Gas Steam Boiler Factories - Coal Fired Thermal Oil Boiler – Double Rings , The product will supply to all over the world, such as: Singapore, Colombia, Mali, All our staffs believe that: Quality builds today and service creates future. We know that good quality and the best service are the only way for us to achieve our customers and to achieve ourselves too. We welcome customers all over the word to contact us for future business relationships. Our products are the best. Once Selected, Perfect Forever!

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.