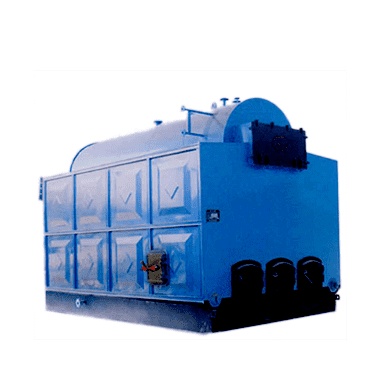

Factory Outlets Thermal Oil Boiler - Gas Oil Thermal Oil Boiler – Double Rings

Factory Outlets Thermal Oil Boiler - Gas Oil Thermal Oil Boiler – Double Rings Detail:

Introduction

The gas-fired Thermol Oil Boiler uses a closed cycle for heat supply and liquid phase transport of heat energy, which has the characteristics of less heat loss, and effectively prolongs the life of the boiler, energy saving and environmental protection. The inside of the furnace adopts a three-circuit tube design and a direct flow structure to ensure the safety of the boiler and effectively extend the service life of the boiler. The coil structure increases the heating surface and has the characteristics of high thermal efficiency. The gas-fired heat-conducting oil boiler adopts countercurrent heat exchange, and the temperature difference between the combustion exhaust temperature and the heat-conducting oil outlet temperature is below 35 ℃. It can work in a lower pressure environment and can reach a working temperature below 450 ℃ to achieve low pressure and high temperature. Now it is widely used in petroleum, chemical, printing and dyeing industries.

Feature

1. Low pressure and high temperature, energy saving, environmental protection, high efficiency and safety.

2. It has safe and reliable operation control and safety monitoring devices, which can accurately control the operating temperature.

3. The structure is scientific and reasonable, the supporting facilities are complete, the installation time is short, and the operation is convenient.

4. It adopts advanced explosion-proof structure, which is suitable for explosion-proof in zone Ⅱ of the factory, and the explosion-proof level can reach C level.

Product detail pictures:

Related Product Guide:

Boiler Structure

"Based on domestic market and expand abroad business" is our enhancement strategy for Factory Outlets Thermal Oil Boiler - Gas Oil Thermal Oil Boiler – Double Rings , The product will supply to all over the world, such as: Washington, London, Milan, "Make the women more attractive "is our sales philosophy. "Being customers' trusted and preferred brand supplier" is the goal of our company. We've been strict with every part of our work. We sincerely welcome friends to negotiate business and start cooperation. We hope to join hands with friends in different industries to create a brilliant future.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.