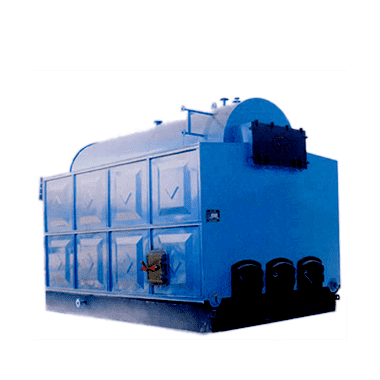

Factory Outlets Commercial Biomass Boilers - DHL Corner Tube Bulk Water Pipe Boiler – Double Rings

Factory Outlets Commercial Biomass Boilers - DHL Corner Tube Bulk Water Pipe Boiler – Double Rings Detail:

Introduction:

As a new type of mature high-performance with low-pollution clean coal technology.

circulating fluidized bed combustion(CFBC)technology is unlike others that it has a lot of unique characteristics.

1. Circulating fluidized bed is of low-temperature combustion, therefore nitrogen oxides emissions of such boiler is much lower than that of coal-powder boiler, and such boiler could directly desulfurize during combustion process. Circulating fluidized bed boiler with high desulfurization rate is economical.

2. Circulating fluidized bed boiler could adopt various coal types and has high combustion efficiency, which is especially suitable for low quality, low calorific value coal.

3.The ash of circulating fluidized bed boiler is of high activity, thus it is easy to realize comprehensive utilization without secondary pollution.

4.Circulating fluidized bed boiler could adjust its load in a wide range. Lowest load can be reduced to 30% Of full capacity.

Our recommendation—the of low magnification circulating fluidized bed boiler products have completely solved the problems like boiler abrasion, slagging and ash blocking of feed recycle device.original emission concentration of boiler and deslagging. Now the requirement on environmental protection is increasingly strict.As raw coal’s proportion of direct-fired is high. which makes the contradiction between coal and environmental protection more and more acute. Under such background, circulating fluidized bed boiler with the features of environmental protection and energy saving is your best choice.

Quality Control

| 1 | Strength Calculation Report for Applied Materials after Inspection Machine inspected. |

| 2 | 100%NDT(non-destructive inspection) report of steel plate,tube and welding rod; |

| 3 | 100% X-ray inspection report (welding seam):to ensure the quality of the entire boiler; |

| 4 | Hydraulic test report:ensure the standard working pressure and safety; |

| 5 | Third-party inspection report:by Special Equipment Safety Supervision Inspection Institute of Jiang Su Province |

| 6 | Manufacturer Produce Level Grade-A. Product Reach European Standard CE Marks. |

Inspection Machinery for the Boiler in Workshop and Laboratory :

| No. | Name | Model | Qty |

| 1 | Digital Carbon & Sulfur Analysis Meter | HV-4B | 1set |

| 2 | High Speed Self-Ignition Furnace | HB-2H | 1set |

| 3 | Electric Scale | JA1003 | 1set |

| 4 | Photometer | 723 | 1set |

| 5 | Metallography Scale | XJB-2A | 1set |

| 6 | Hydraulic Multi-propose Test Machinery | WE-100 | 1set |

| 7 | WE-600A | 1set | |

| 8 | Concussion Testing Machine | JB-30 | 1set |

| 9 | Projective Meter | JS | 1set |

| 10 | X Ray Crack Detector | XXH3005 | 1set |

| 11 | XXH2505 XXXXH23005 | 2sets | |

| 12 | XY2515 | 2sets | |

| 13 | Ultrasonic Crack Detector | CTS-22 | 2sets |

Product detail pictures:

Related Product Guide:

Boiler Structure

To be able to ideal satisfy client's requirements, all of our operations are strictly performed in line with our motto "High High-quality, Competitive Price tag, Fast Service" for Factory Outlets Commercial Biomass Boilers - DHL Corner Tube Bulk Water Pipe Boiler – Double Rings , The product will supply to all over the world, such as: Croatia, Netherlands, Mexico, To make every client satisfied with us and achieve win-win success, we will continue to try our best to serve and satisfy you! Sincerely looking forward to cooperating with more overseas customers based on mutual benefits and great future business. Thank you.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.