Factory Free sample Outdoor Coal Boiler - Boiler Valve and Meter – Double Rings

Factory Free sample Outdoor Coal Boiler - Boiler Valve and Meter – Double Rings Detail:

Quality Control

| 1 | Strength Calculation Report for Applied Materials after Inspection Machine inspected. |

| 2 | 100%NDT(non-destructive inspection) report of steel plate,tube and welding rod; |

| 3 | 100% X-ray inspection report (welding seam):to ensure the quality of the entire boiler; |

| 4 | Hydraulic test report:ensure the standard working pressure and safety; |

| 5 | Third-party inspection report:by Special Equipment Safety Supervision Inspection Institute of Jiang Su Province |

| 6 | Manufacturer Produce Level Grade-A. Product Reach European Standard CE Marks. |

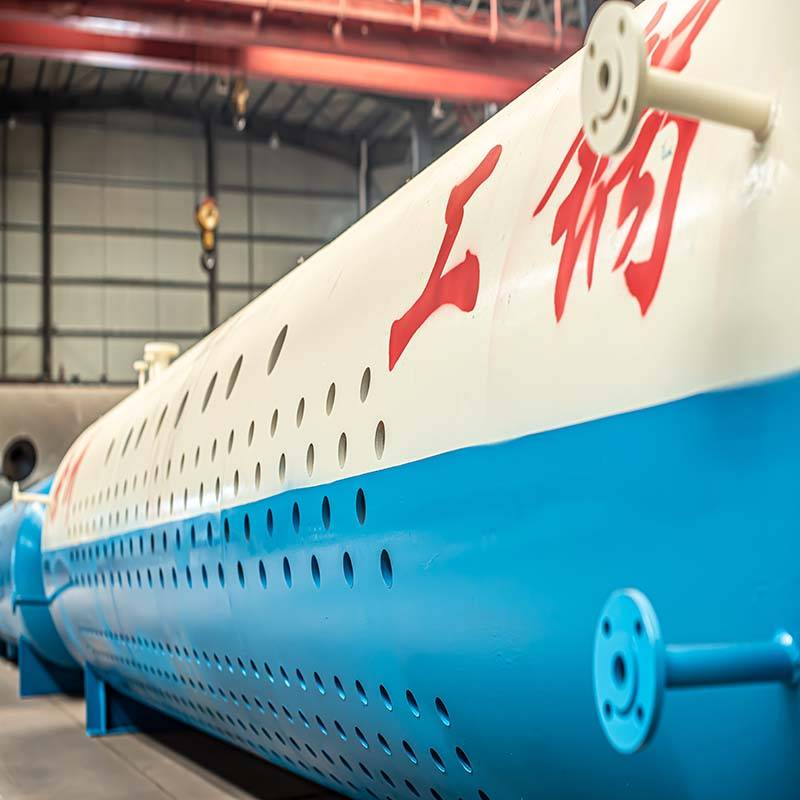

Product detail pictures:

Related Product Guide:

Boiler Structure

Often customer-oriented, and it's our ultimate target to become not only probably the most reputable, trustable and honest provider, but also the partner for our customers for Factory Free sample Outdoor Coal Boiler - Boiler Valve and Meter – Double Rings , The product will supply to all over the world, such as: Amsterdam, Liberia, Vietnam, Our products are very popular in the word, like South American, Africa, Asia and so on. Companies to "create first-class products" as the goal, and strive to deliver customers with high quality solutions, present high-quality after-sales service and technical support, and customer mutual benefit, create a better career and future!

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

Write your message here and send it to us