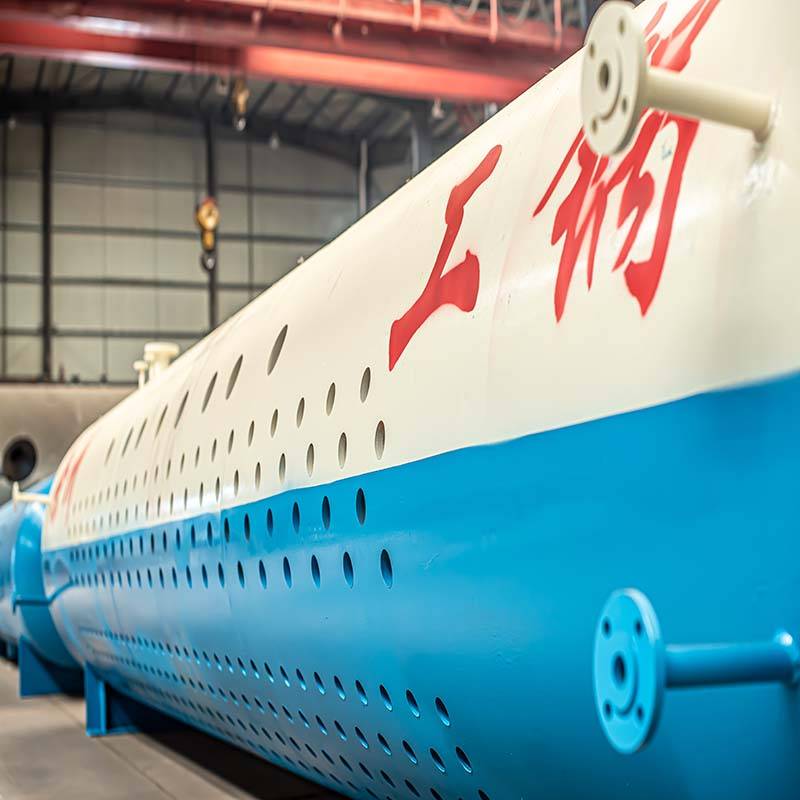

Circulating Fluidized Bed Factory - Vertical Gas Oil Boiler – Double Rings

Circulating Fluidized Bed Factory - Vertical Gas Oil Boiler – Double Rings Detail:

Introduction :

1. Compact structure, small installation area, easy to install.

2. Good heating surface , low exhaust gas temperature

3. The world famous original burner, automatic and high efficient combustion, high combustion efficiency

4. Microcomputer automatic controller, overpressure protection and ultra-low water level automatic protection and automatic feed water .

5. Super thickness insulating layer design, good insulation effect, boiler surface temperature low, low losing heating.

6. Small dust emission to achieve the requirements of the national environmental safety.

Steam Boiler Parameter

LHS Vertical Steam Boiler burning oil or gas

Main Technology Parameter List

| ModelItem | LHS0.1-0.4-YQLHS0.1-0.7-YQ | LHS0.2-0.4-YQLHS0.2-0.7-YQ | LHS0.3-0.4-YQLHS0.3-0.7-YQ | LHS0.5-0.4-YQLHS0.5-0.7-YQ | LHS0.7-0.4-YQLHS0.7-0.7-YQ | LHS1-0.4-YQLHS1-0.7-YQLHS1-1.0-YQ |

| Rated Capacity T/h |

0.1 |

0.2 |

0.3 |

0.5 |

0.7 |

1.0 |

| Rated Working Pressure |

0.4/0.7 Mpa |

0.4/0.7 Mpa |

0.4/0.7 Mpa |

0.4/0.7 Mpa |

0.4/0.7 Mpa |

0.4/0.7 Mpa |

| Rated Steam Temp. ℃ |

152/170 |

151.8/170 |

151.8/170 |

151.8/170 |

151.8/170 |

151.8/170/183 |

| Feed Water Temp. ℃ |

20 |

|||||

| Heating Surface m² |

2.3 |

4.34 |

6.53 |

12.05 |

20.93 |

25.48 |

| Installed Overall Dimension |

1.26×1.25×1.97 |

1.456×1.35×2.07 |

1.91×1.68×2.475 |

2.15×1.9×2.735 |

1.54×2.3×2.855 |

2.963×2.35×3.07 |

| Boiler Weight Ton |

1 |

1.15 |

1.67 |

2.57 |

2.96 |

4.03 |

| Water Pump Model |

JGGC 0.6-8 |

JGGC 0.6-8 |

JGGC 0.6-8 |

JGGC 0.6-12 |

JGGC 0.6-12 |

JGGC 2-10 |

| Chimney mm |

Ø 150 |

Ø 150 |

Ø 200 |

Ø 200 |

Ø 300 |

Ø 300 |

| Thermal Efficiency % |

83 |

83 |

83 |

83 |

83 |

83 |

| Design Fuel |

Light Oil/Town Gas/Natural Gas |

|||||

| Burner Brand` |

Italy RIELLO Burner G20S |

|||||

| Ringelmann shade |

< Grade 1 |

|||||

Hot Water Boiler Parameter

Atmospheric Pressure Hot Water Boiler burning gas or oil

Main Parameter List

|

Model Item |

CLHS0.21-95/ 70-Y(Q)

|

CLHS0.35-95/ 70-Y(Q)

|

CLHS0.5-95/ 70-Y(Q)

|

CLHS0.7-95/ 70-Y(Q)

|

CLHS1.05-95/ 70-Y(Q)

|

CLHS1.4-95/ 70-Y(Q)

|

|

Rated Thermal Power MW |

0.21 |

0.35 |

0.5 |

0.7 |

1.05 |

1.4 |

|

Rated Outlet Water Temp. ℃ |

95 |

|||||

|

Rated Return Water Temp. ℃ |

20 |

|||||

|

Design Fuel |

Heavy oil/0# Light Diesel oil/ Natural Gas |

|||||

|

Heating Surface m² |

10.5 |

12.6 |

15 |

16.5 |

22 |

35.6 |

|

Design Thermal efficiency |

83% |

|||||

|

Heating Area m² |

1800 |

3000 |

4300 |

6000 |

9000 |

12000 |

|

Boiler Body Specification mm |

Ø1164×2040 |

Ø1164×2550 |

Ø1264×2550 |

Ø1364×2360 |

Ø1468×2590 |

Ø1568×2830 |

|

Boiler Weight Ton |

1.7 |

1.9 |

2.5 |

3.0 |

3.1 |

3.8 |

|

Dust emission |

< 100 mg/Nm3 |

|||||

|

Ringelmann shade |

< Grade 1 |

|||||

Product detail pictures:

Related Product Guide:

Boiler Structure

Our corporation insists all along the quality policy of "product top quality is base of organization survival; purchaser pleasure will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" plus the consistent purpose of "reputation very first, purchaser first" for Circulating Fluidized Bed Factory - Vertical Gas Oil Boiler – Double Rings , The product will supply to all over the world, such as: Myanmar, Guatemala, Malawi, we have complete material production line, assembling line , quality control system, and the most importantly, we have many patents technology and experienced technical&production team, professional sales service team. With all those advantages, we are going to create"the reputable international brand of nylon monofilaments", and spreading our products to every corner of the world. We are keep moving and try our best to serve our customers.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.