Chinese wholesale Lpg Steam Boiler - Biomass Wood Thermal Oil Boiler – Double Rings

Chinese wholesale Lpg Steam Boiler - Biomass Wood Thermal Oil Boiler – Double Rings Detail:

Thermal Oil Boiler used in Textile,Foods, Rubber ,Paper, Plastic, Wood, Building Materials etc.

Feature:

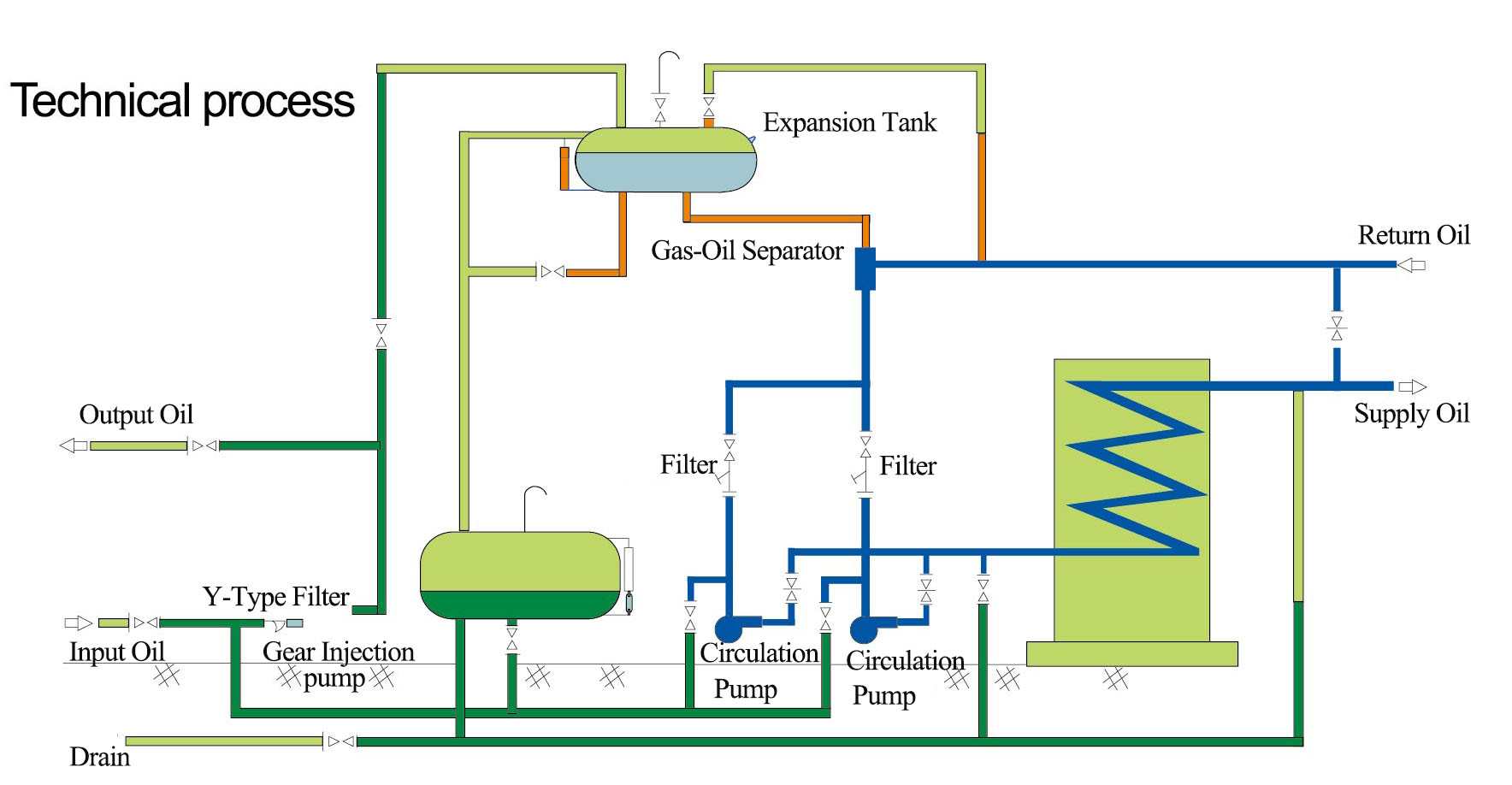

1.Overall structure is reasonable and compact, easy to install.

2.Advanced design, Complete structure

3. Simple water cycle, reasonable structure of pressure parts, guarantee water quality, safe to run

4. Complete Ancillary equipment, advanced comprehensive technology

Product detail pictures:

Related Product Guide:

Boiler Structure

Sticking to the principle of "Super Quality, Satisfactory service" ,We are striving to be a good business partner of you for Chinese wholesale Lpg Steam Boiler - Biomass Wood Thermal Oil Boiler – Double Rings , The product will supply to all over the world, such as: Southampton, Swiss, Georgia, We insist on "Quality First, Reputation First and Customer First". We are committed to providing high-quality products and good after-sales services. Up to now, our products have been exported to more than 60 countries and areas around the world, such as America, Australia and Europe. We enjoy a high reputation at home and abroad. Always persisting in the principle of "Credit, Customer and Quality", we expect cooperation with people in all walks of life for mutual benefits.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!

Write your message here and send it to us