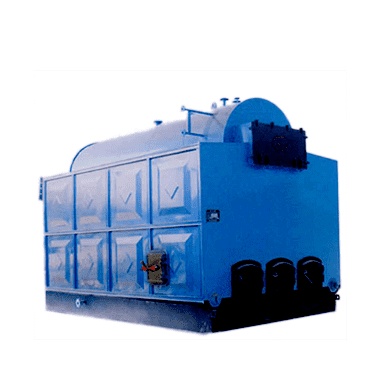

China Manufacturer for Electric Steam Generator - Coal Boiler Biomass Boiler Slag Remover – Double Rings

China Manufacturer for Electric Steam Generator - Coal Boiler Biomass Boiler Slag Remover – Double Rings Detail:

Slag Remover used in Coal Boiler

Introduction

The Slag Remover is a kind of boiler slag tapping equipment. The carbon slag produced after the coal is burned in the boiler is pushed to the slag storage pit by the grate, and is dragged out of the furnace by the slag machine to clear the slag accumulation.

Technology

The high-temperature slag discharged from the furnace is first crushed into small pieces by a pair-roller slag breaker, which is convenient for cooling and transportation; the crushed slag enters the water-cooled spiral slag discharger and the spiral blades and outer cylinder are fully exchanged. The heat is discharged after cooling. If necessary, an air lock (star ash unloading valve) can also be configured at the outlet of the slag cooler. The ash inlet temperature is less than 900℃, the slag size is less than 100MM, the conveying distance is 4-7M, horizontal installation.

Advantage

1. It is convenient for comprehensive utilization of slag.

2. Reasonable structure design, reliable operation, safe operation and good sealing performance.

3. Good load adaptability and convenient for remote control.

Product detail pictures:

Related Product Guide:

Boiler Structure

We take pleasure in an extremely fantastic standing among the our prospects for our great product top quality, competitive cost and the finest support for China Manufacturer for Electric Steam Generator - Coal Boiler Biomass Boiler Slag Remover – Double Rings , The product will supply to all over the world, such as: Frankfurt, Panama, Stuttgart, We are your reliable partner in international markets with the best quality products. Our advantages are innovation, flexibility and reliability which have been built during the last twenty years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sales and after-sales service ensures strong competitiveness in an increasingly globalized market.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!