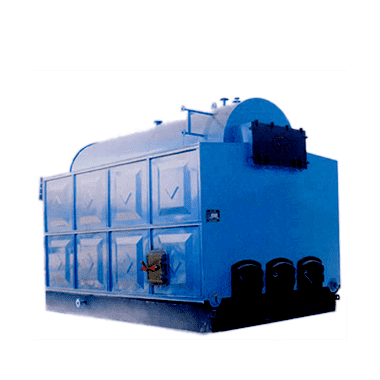

Cheap PriceList for Industrial Biomass Boiler - Boiler Water Tank – Double Rings

Cheap PriceList for Industrial Biomass Boiler - Boiler Water Tank – Double Rings Detail:

Used in Boiler

Tank accessories

(1) Water inlet pipe: The water inlet pipe of the water tank is generally connected from the side wall, but it can also be connected from the bottom or top.

When the water tank USES the pipe network pressure to fill the water, the inlet pipe outlet should be equipped with a floating ball valve or hydraulic valve.

Generally, there are not less than 2 floating ball valves.

The diameter of the ball float valve is the same as that of the inlet pipe, and each ball float valve shall be equipped with an inspection valve before it.

(2) Outlet pipe: the outlet pipe of the water tank can be connected from the side wall or the bottom.

The bottom of the outlet pipe connected from the side wall or the top surface of the outlet pipe connected from the bottom shall be 50 mm higher than the bottom of the water tank.

The outlet pipe shall be equipped with gate valve.

The inlet and outlet pipes of the water tank should be set separately. When the inlet and outlet pipes are the same pipe, check valve should be installed on the outlet pipe.

When it is necessary to install check valves, swing check valves with less resistance should be used instead of lifting check valves, and the elevation should be more than 1m below the lowest water level of the water tank.

When a water tank is used jointly by life and fire control, the check valve on the fire control outlet pipe should be lower than the pipe top of the domestic water outflow siphon (when the vacuum of the domestic siphon is destroyed when the water is lower than the pipe top, only the water flow out of the fire control outlet pipe is guaranteed at least 2M, so that it has a certain pressure to push the check valve.

When a fire occurs, the fire water reserve can really play a role.

(3) Overflow pipe: the overflow pipe of the water tank can be connected out from the side wall or the bottom, and its pipe diameter shall be determined according to the maximum inlet flow of the discharge tank, and shall be larger than the intake pipe L-2.

Valves shall not be installed on the overflow pipe.

The overflow pipe shall not be directly connected with the drainage system, and indirect drainage shall be adopted. Measures shall be taken on the overflow pipe to prevent the entry of dust, insects, mosquitoes and flies, such as water seal and filter screen, etc.

(4) Drain pipe: the water tank drain pipe should be connected from the lowest part of the bottom.

Drain pipe Figure 2-2N The water tank for fire fighting and living table is equipped with a gate valve (should not be equipped with a cut-off valve), which can be connected with the overflow pipe, but not directly connected with the drainage system.

Drainage pipe diameter generally adopts DN50 when there is no special requirement.

(5) Ventilation pipe: The water tank for drinking water shall be provided with a sealed box cover, and the box cover shall be provided with access hole and ventilation pipe.

Ventilation pipe can be extended to indoor or outdoor, but not to harmful gases. The nozzle should have a filter screen to prevent dust, insects and flies from entering. Generally, the nozzle should be set down.

Ventilation pipe shall not be equipped with valves, water seals and other devices that interfere with ventilation.

Ventilation pipe shall not be connected with drainage system and ventilation duct.

Ventilation pipe generally adopts the diameter of DN50.

(6) Liquid level meter: Generally, glass liquid level meter should be installed on the side wall of the water tank to indicate the water level on the spot.

When the length of one liquid level gauge is insufficient, two or more liquid level gauges can be installed up and down.

The overlap part of two adjacent liquid level gauges should not be less than 70mm, as shown in Figure 2-22.

If there is no liquid level signal timing in the water tank, signal tube can be set to give the overflow signal.

The signal tube is generally connected from the side wall of the water tank, and its height should be set so that the bottom of the tube is level with the bottom of the overflow tube or the overflow water surface of the flared mouth.

Generally, the diameter of the pipe is DNl5 signal pipe, which can be connected to the washbasin, washing basin and other places in the room where there are often people on duty.

If the level of the water tank is interlocked with the water pump, the level relay or signal device shall be installed on the side wall or top cover of the water tank. The commonly used level relay or signal device includes float ball type, pole type, capacitance type and float type, etc.

The high and low electric hanging water level of the water tank with water pump pressure should be considered to maintain a certain safe volume. The maximum electric control water level at the moment of stopping the pump should be 100 mm lower than the overflow water level, while the minimum electric control water level at the moment of starting the pump should be 20mm higher than the design minimum water level, so as to avoid overflow or cavitation caused by error.

(7) Water tank cover, internal and external ladder.

Product detail pictures:

Related Product Guide:

Boiler Structure

Being supported by an state-of-the-art and skilled IT team, we could supply technical support on pre-sales & after-sales service for Cheap PriceList for Industrial Biomass Boiler - Boiler Water Tank – Double Rings , The product will supply to all over the world, such as: Georgia, Jamaica, Estonia, We've been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we've the whole capacity to provide you happy solutions.

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.