The difference between the total heat released by the complete combustion of the fuel in the boiler and the heat used by the boiler. Including the heat taken away by the flue gas discharged from the boiler, the heat lost to the surrounding air by the furnace body, the heat that has not been emitted after the fuel has not been burned or incompletely burned, and the physical heat taken away by the ash and slag. These losses are expressed as a percentage of the total heat released by the complete combustion of the fuel.

The total heat carried by the fuel into the boiler is not absorbed by the working fluid in the boiler. Heat loss includes: exhaust smoke loss; gas incomplete combustion heat loss; solid incomplete combustion heat loss; heat loss; ash and slag physical heat loss

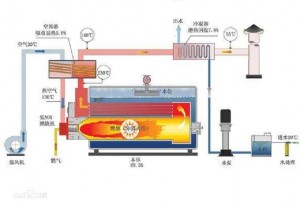

The heat loss of the boiler mainly includes the following items:

Exhaust heat loss

The exhaust temperature of industrial boilers is relatively high, between 200 and 300 degrees. Such a high exhaust temperature means that a large part of the heat in the fuel is taken away by the flue gas and lost in the atmosphere, causing heat loss in the exhaust of the boiler. The higher the exhaust gas temperature, the greater the exhaust heat loss. Generally, the exhaust heat loss can be reduced by about 1% every time the exhaust temperature is reduced by 15 to 20 degrees.

In order to reduce the heat loss of exhaust gas, methods of increasing the heating surface at the tail are often used, such as adding economizers and air preheaters, etc., but the exhaust gas temperature cannot be reduced too much, otherwise it will cause the boiler metal consumption to increase more and the tail The possibility of low-temperature corrosion on the heated surface increases. In addition, when the boiler is running, it is possible to reduce the heat loss of exhaust gas by frequently cleaning the ash, controlling the excess air coefficient and reducing air leakage at various places in the flue.

Incomplete combustion

In the flue gas, a part of the combustible gas is not completely combusted in the furnace and is discharged with the flue gas. This part of the heat loss is called the heat loss of gas incomplete combustion. If the size of the furnace is too small and the height is not enough, the combustible gas will enter the low-temperature flue before it can burn, which will cause the heat loss of incomplete combustion of the gas. Adding secondary air to the boiler can enhance the mixing of air and combustible gas and promote complete combustion.

Solid incomplete combustion

In the process of solid fuel combustion, there is often a part of the fuel that does not burn and leaves the boiler with ash or fly ash. This part of heat loss is called solid incomplete combustion heat loss. For solid fuel boilers, the heat loss from incomplete solid combustion is the main heat loss in the total heat loss. The more ash, the more combustibles trapped in the ash and the greater the heat loss.

Heat loss

During the operation of the boiler, the temperature of the furnace wall and the outer wall of the boiler body is always higher than the temperature of the surrounding air, which will cause heat loss and heat dissipation loss. The heat loss is related to the outer surface area of the boiler, the degree of heat insulation, the temperature of the outside air and the air flow velocity. It is generally required that the temperature of the furnace wall surface should not exceed 50 degrees.

Reduction methodedit

The automatic adjustment of combustion is to adjust the amount of fuel under the premise of controlling the steam pressure at the outlet of the boiler to a certain value; in order to achieve reasonable combustion, the quality of combustion must also be controlled, which can be based on the oxygen content of the flue gas at the boiler exhaust. To control the ventilation system and adjust the ventilation volume to maintain an appropriate amount of air excess coefficient and reduce the heat loss of the boiler. Therefore, a complete combustion adjustment actually includes boiler steam pressure adjustment, combustion setting, combustion volume adjustment, air volume adjustment, furnace negative pressure adjustment, and blower and induced draft fan control.

Post time: Jun-03-2021