Bottom price Coal Fired Boiler - Boiler Water Treatment – Double Rings

Bottom price Coal Fired Boiler - Boiler Water Treatment – Double Rings Detail:

More photos

1. Quartz sand filter — mainly used for the removal of sediment from water.

2. Active Carbon filter– mainly used for chlorine removal and other organic gases and to clear up the taste of water .

3. Water Softener– exchange “ions” of calcium and magnesium with the most common and easiest method.

4. Precision filter– mainly used for removing microorganisms,chlorine,part of the heavy metal ions more precisely

5. High pressure pump– Provide the high pressure to RO membrane ro.

6. RO system– main part of the plant. The RO membrane’s desalting rate can reach 99%, removing over 99% ions.

RO membranes combine auto wash and manual wash together which can protect RO membrane easily.

7. Ozone generator – Kills 99.9 percent of known harmful bacteria.

Product detail pictures:

Related Product Guide:

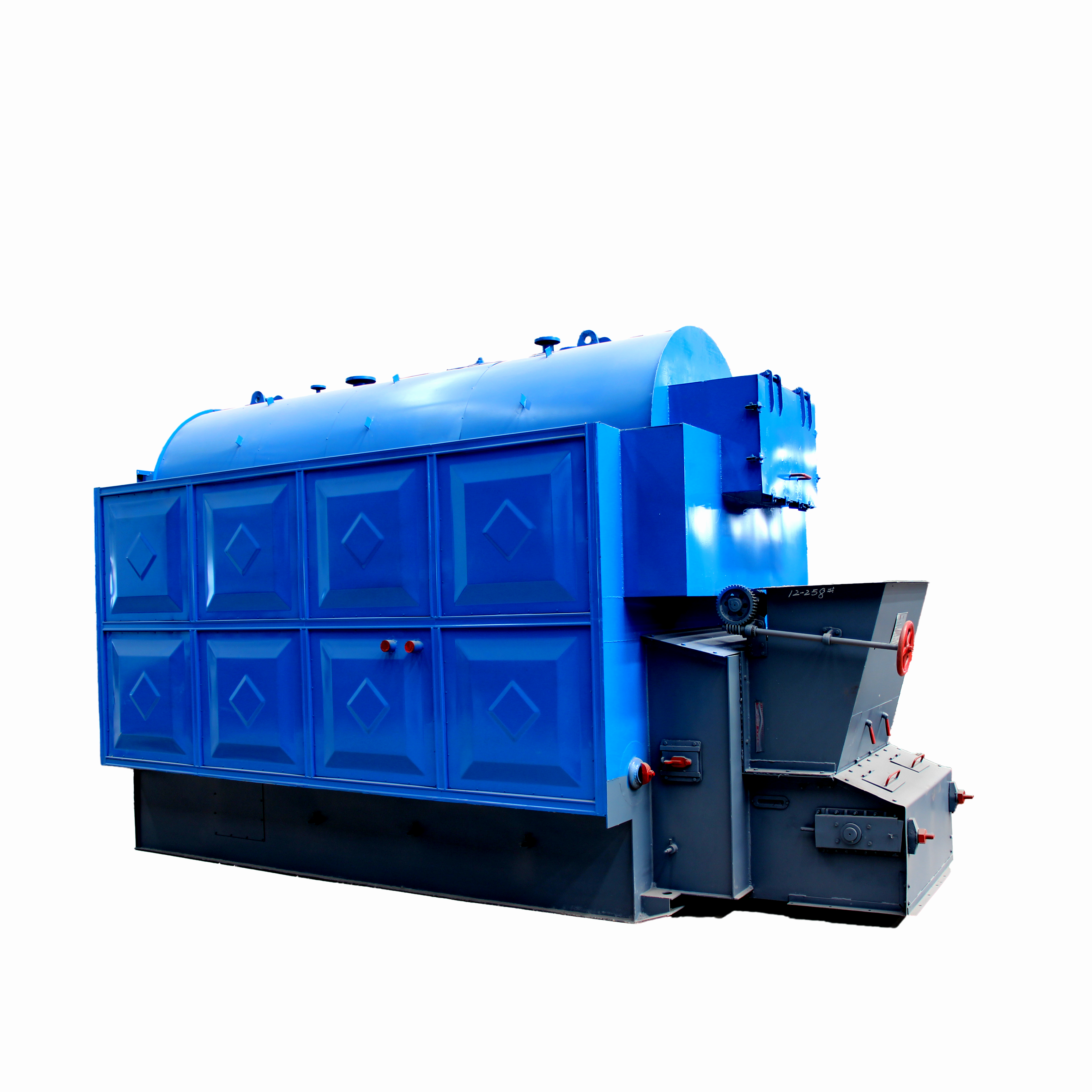

Boiler Structure

We always work as a tangible team to ensure that we can provide you with the best quality and the best price for Bottom price Coal Fired Boiler - Boiler Water Treatment – Double Rings , The product will supply to all over the world, such as: Mauritius, Malaysia, Borussia Dortmund, With a wide range, good quality, reasonable prices and stylish designs, our items are extensively used in this field and other industries. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success! We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!