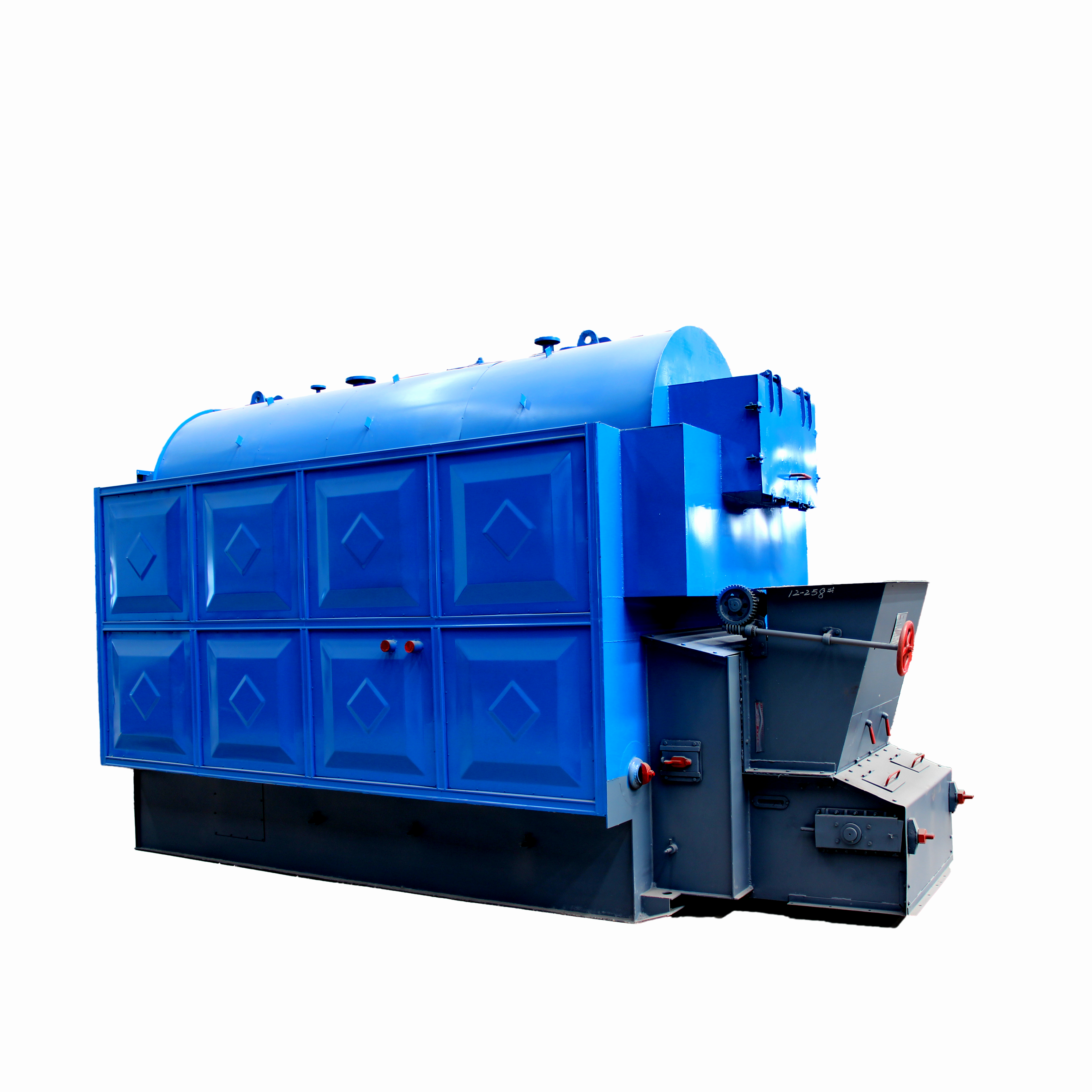

Biomass Steam Boilers Manufacturers - Coal Boiler Biomass Boiler Slag Remover – Double Rings

Biomass Steam Boilers Manufacturers - Coal Boiler Biomass Boiler Slag Remover – Double Rings Detail:

Slag Remover used in Coal Boiler

Introduction

The Slag Remover is a kind of boiler slag tapping equipment. The carbon slag produced after the coal is burned in the boiler is pushed to the slag storage pit by the grate, and is dragged out of the furnace by the slag machine to clear the slag accumulation.

Technology

The high-temperature slag discharged from the furnace is first crushed into small pieces by a pair-roller slag breaker, which is convenient for cooling and transportation; the crushed slag enters the water-cooled spiral slag discharger and the spiral blades and outer cylinder are fully exchanged. The heat is discharged after cooling. If necessary, an air lock (star ash unloading valve) can also be configured at the outlet of the slag cooler. The ash inlet temperature is less than 900℃, the slag size is less than 100MM, the conveying distance is 4-7M, horizontal installation.

Advantage

1. It is convenient for comprehensive utilization of slag.

2. Reasonable structure design, reliable operation, safe operation and good sealing performance.

3. Good load adaptability and convenient for remote control.

Product detail pictures:

Related Product Guide:

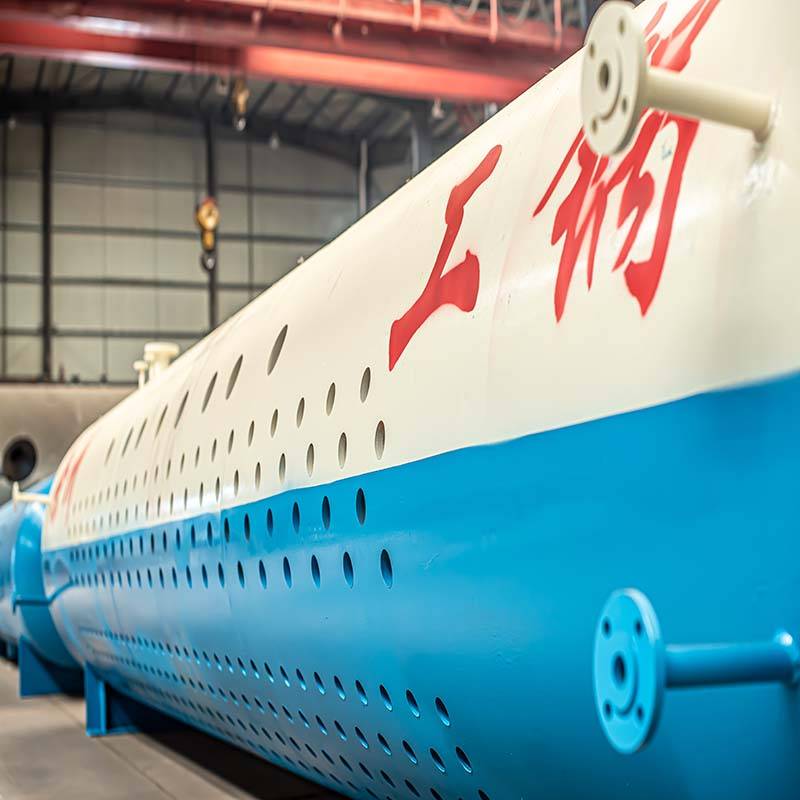

Boiler Structure

As a way to present you with ease and enlarge our enterprise, we also have inspectors in QC Workforce and assure you our greatest support and solution for Biomass Steam Boilers Manufacturers - Coal Boiler Biomass Boiler Slag Remover – Double Rings , The product will supply to all over the world, such as: Mumbai, Los Angeles, Seychelles, Our company has already have pass the ISO standard and we are fully respect our customer 's patents and copyrights. If the customer provides their own designs, We will guarantee that they will be the only one can have that products. We hoping that with our good products can bring our customers a great fortune.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.