Best quality Boiler Manufacturers - Gas oil Boiler Burner – Double Rings

Best quality Boiler Manufacturers - Gas oil Boiler Burner – Double Rings Detail:

More photos

•Single stage operation(on/off).

•Air-gas mixing at blast-pipe.

•Ability to obtain optimal combustion values by regulating combustion air and blast-pipe.

•Maintenance facilitated by the fact that the atomisation unit can be removed without having to remove the burner from the boiler.

•Single stage manual flow adjustment

•Sliding/modulating The servo motor which fixed with a cam can adjust the consumption for fuel and air.

•One flange and one insulating seal for boiler fastening.

•Combustion air intake with air flow adjustment device.

•Sliding boiler coupling flange to adapt to head protrusion of the various types of boilers.

•one-way electric motor to run fan.

Product detail pictures:

Related Product Guide:

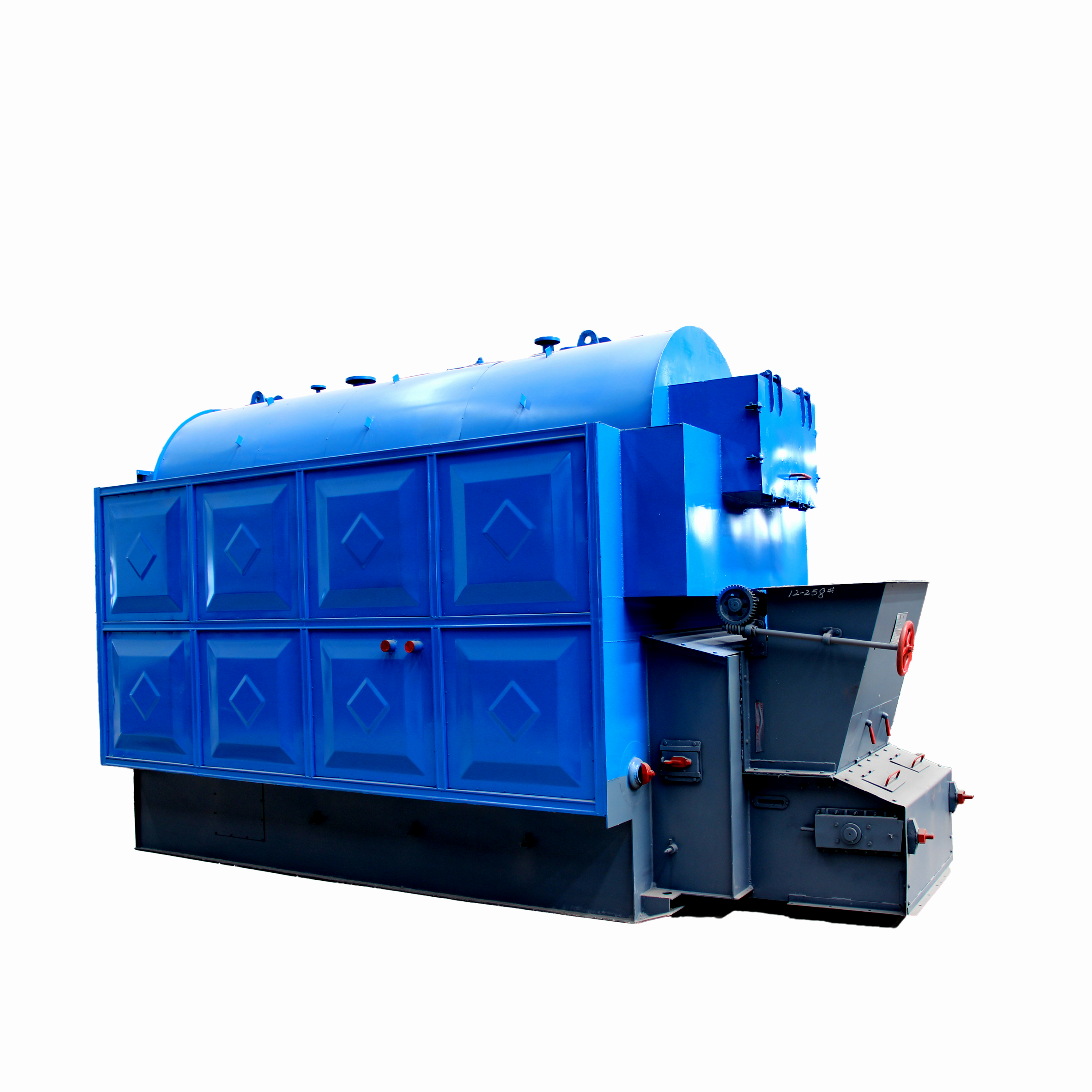

Boiler Structure

We emphasize advancement and introduce new products into the market each year for Best quality Boiler Manufacturers - Gas oil Boiler Burner – Double Rings , The product will supply to all over the world, such as: Costa rica, French, Pakistan, If you give us a list of products you are interested in, along with makes and models, we can send you quotations. Please email us directly. Our goal is to establish long-term and mutually profitable business relationships with domestic and overseas clients. We look forward to receiving your reply soon.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.

Write your message here and send it to us