18 Years Factory Industrial Electric Boiler - Coal Boiler Biomass Boiler Multi-Tube Dust Cleaner – Double Rings

18 Years Factory Industrial Electric Boiler - Coal Boiler Biomass Boiler Multi-Tube Dust Cleaner – Double Rings Detail:

Used in Boiler

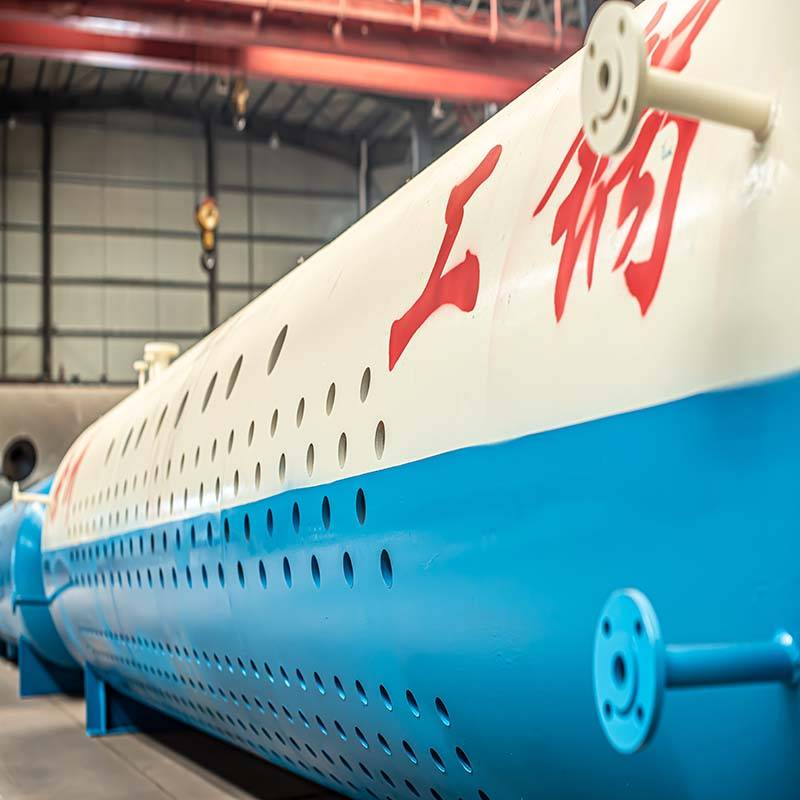

Multi-tube dust collector belongs to cyclone type dry dust collector, mainly used for boiler and industrial dust collection. Multi-tube dust collector, a kind of cyclone dust collector. Many small cyclone dust collectors (also called cyclones) are combined in a shell and used in parallel. The diameter of the cyclone varies from 100 to 250 mm and can effectively trap 5 to 10 μm dust. It is cast with wear-resistant cast iron and can handle gas with high dust concentration (100g/m3).

Product detail pictures:

Related Product Guide:

Boiler Structure

To be a result of ours specialty and repair consciousness, our corporation has won a good popularity amid consumers everywhere in the environment for 18 Years Factory Industrial Electric Boiler - Coal Boiler Biomass Boiler Multi-Tube Dust Cleaner – Double Rings , The product will supply to all over the world, such as: South Africa, Milan, Hungary, It is our customers' satisfaction over our products and services that always inspires us to do better in this business. We build mutually beneficial relationship with our clients by giving them large selection of premium car parts at marked down prices. We provide wholesale prices on all our quality parts so you are guaranteed greater savings.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.

Write your message here and send it to us