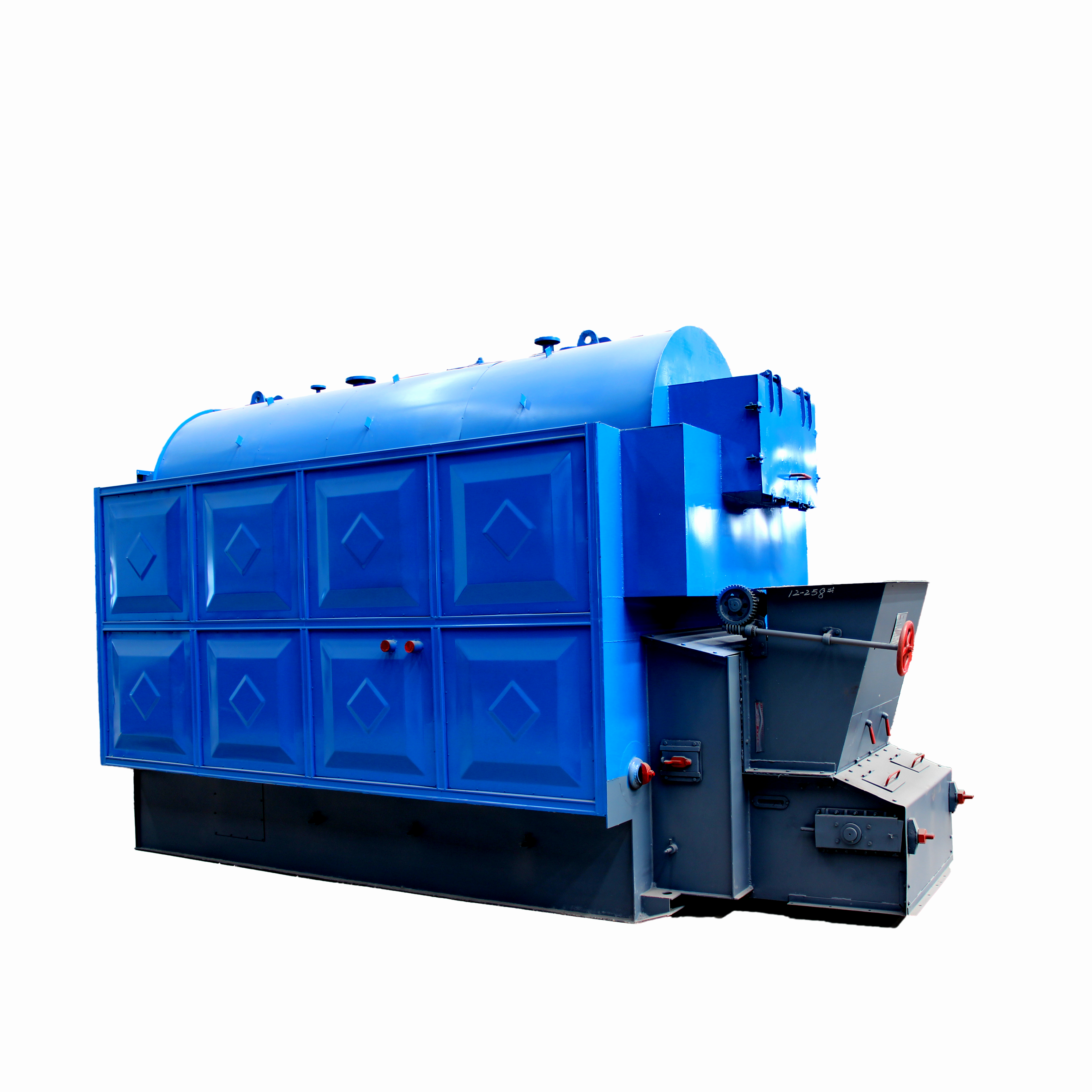

100% Original Oil Fired Boilers - Double Drum Hot Water Boiler – Double Rings

100% Original Oil Fired Boilers - Double Drum Hot Water Boiler – Double Rings Detail:

Parameter :

SZL Bearing Pressure Hot water Boiler

Main Technology Parameter List

| ModelItem | SZL2.8-1.0/115/70-AIISZL2.8-1.25/130/70-AII | SZL4.2-1.0/115/70-AIISZL4.2-1.25/130/70-AII | SZL5.6-1.0/115/70-AIISZL5.6-1.25/130/70-AII | |||

| Rated Capacity | 2.8T/h | 4.2 T/h | 5.6 T/h | |||

| Rated Working Pressure Mpa | 1.0/1.25 | 1.0/1.25 | 1.0/1.25 | |||

| Rated Steam Temp. ℃ | 115/130 | 115/130 | 115/130 | |||

| Feed Water Temp. ℃ | 70 | 70 | 70 | |||

| Fuel Consumption Kg/H | ~580 | ~900 | ~1130 | |||

| Thermal Efficiency % | 78 | 80 | 80 | |||

| Heating Surface | Boiler Body m² | 80.5 | 142 | 178 | ||

| Economizer m² | 38.5 | 87.2 | 122.08 | |||

| Grate area m² | 4.84 | 7.78 | 10.42 | |||

| Design Fule | Bituminous Coal | |||||

| Max. Transport Weight | 30 T | ~25T | ~26T | |||

| Max. Transport Dimension m | 6.9×2.5×3.5 | Up6.09×3.04×3.6D:7.3×2.86×1.72 | 6.9×3.33×3.55 | |||

| Boiler Auxiliary Equipment Model and Specification | ||||||

| Air Blower | Model | T4-72-11 4ARight 315° | T4-72-11 5ARight 225° | GC8-1Right 225° | ||

| Motor Power | N=5.5 Kw | N=11 Kw | N=11 Kw | |||

| Draft Fan | Model | Y9-26 9DRight 0° | Y8-39 9DRight 0° | GY8-1Right 0° | ||

| Motor Power | N=22 Kw | N=30 Kw | N=37 Kw | |||

| Gear Box | Model | GL-5P | GL-10P | GL-10P | ||

| Motor Power | N=0.55 Kw | N=1.1Kw | N=1.1 Kw | |||

| Feed Water Pump | Model | 1½ GC5x7 | 2GC-5×5 | 2GC-5×4 | ||

| Motor Power | N=7.5 Kw | N=11 Kw | N=11 Kw | |||

| Dust Remover | XD-4 | XD-6 | XD-8 | |||

| ModelItem | SZL7-1.0/115/70-AIISZL7-1.25/130/70-AII | SZL10.5-1.0/115/70-AIISZL10.5-1.25/130/70-AII | SZL14-1.0/115/70-AIISZL14-1.25/130/70-AII | SZL17.5-1.0/115/70-AIISZL17.5-1.25/130/70-AII | |

| Rated Capacity | 7T/h | 10.5 T/h | 14 T/h | 17.5T/h | |

| Rated Working Pressure Mpa | 1.0/1.25 | 1.0/1.25 | 1.0/1.25 | 1.0/1.25 | |

| Rated Steam Temp. ℃ | 115/130 | 115/130 | 115/130 | 115/130 | |

| Feed Water Temp. ℃ | 70 | 70 | 70 | 70 | |

| Fuel Consumption Kg/H | ~1400 | ~1900 | ~2700 | ~3650 | |

| Thermal Efficiency % | 82 | 82 | 82 | 82 | |

| Heating Surface m² | Radiation Tube | 39.43 | 37.21 | 58.4 | 58.4/68.4 |

| convection bank | 213.4 | 284.68 | 307.4 | 307.4/384.8 | |

| Economizer m² | 122.08 | 130.8 | 413 | 413/521 | |

| Grate area m² | 11.99 | 17.81 | 22.56 | 24.52 | |

| Design Fule | Bituminous Coal (Low location of heat value:19228Ki/kg) | ||||

| Max. Transport Weight | ~40 T | ~43T | ~30T | ~30T | |

| Max. Transport Dimension | 7.9×3.2×3.5 | 10×3.2×3.5 | 11×3.2×3.5 | 12×3.2×3.54 | |

Product detail pictures:

Related Product Guide:

Boiler Structure

The organization keeps for the procedure concept "scientific administration, superior quality and effectiveness primacy, shopper supreme for 100% Original Oil Fired Boilers - Double Drum Hot Water Boiler – Double Rings , The product will supply to all over the world, such as: Moscow, Botswana, Pretoria, We warmly welcome you to come to visit us personally. We hope to establish a long-term friendship based on equality and mutual benefit. If you want to get in touch with us, please do not hesitate to call. We will be your best choice.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.

Write your message here and send it to us