Wholesale Fire Tube Boiler Manufacturer - Coal Boiler Biomass Boiler Water Flim Dust Cleaner – Double Rings

Wholesale Fire Tube Boiler Manufacturer - Coal Boiler Biomass Boiler Water Flim Dust Cleaner – Double Rings Detail:

Quality Control

| 1 | Strength Calculation Report for Applied Materials after Inspection Machine inspected. |

| 2 | 100%NDT(non-destructive inspection) report of steel plate,tube and welding rod; |

| 3 | 100% X-ray inspection report (welding seam):to ensure the quality of the entire boiler; |

| 4 | Hydraulic test report:ensure the standard working pressure and safety; |

| 5 | Third-party inspection report:by Special Equipment Safety Supervision Inspection Institute of Jiang Su Province |

| 6 | Manufacturer Produce Level Grade-A. Product Reach European Standard CE Marks. |

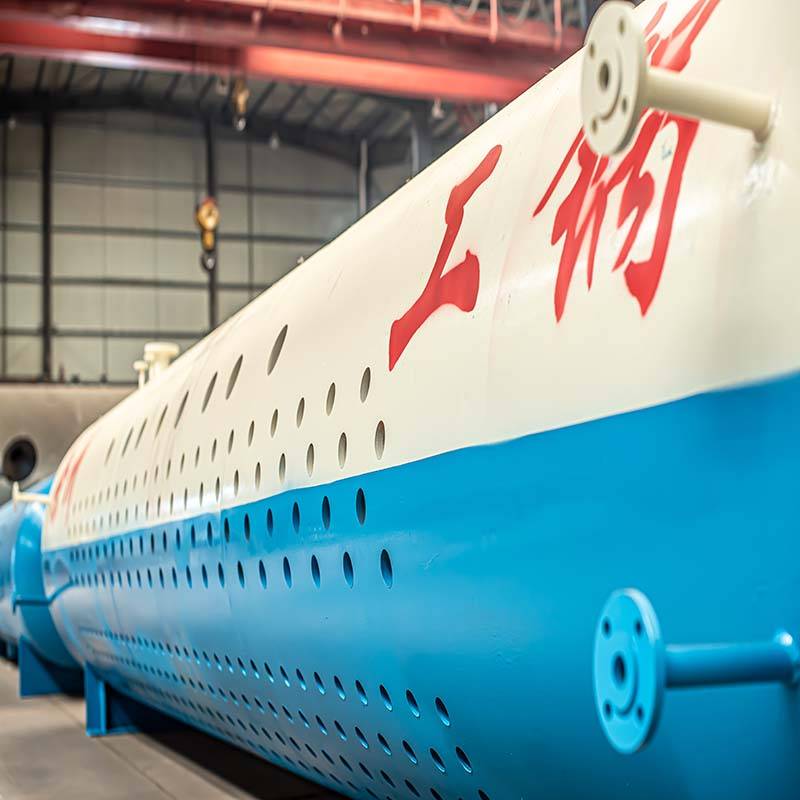

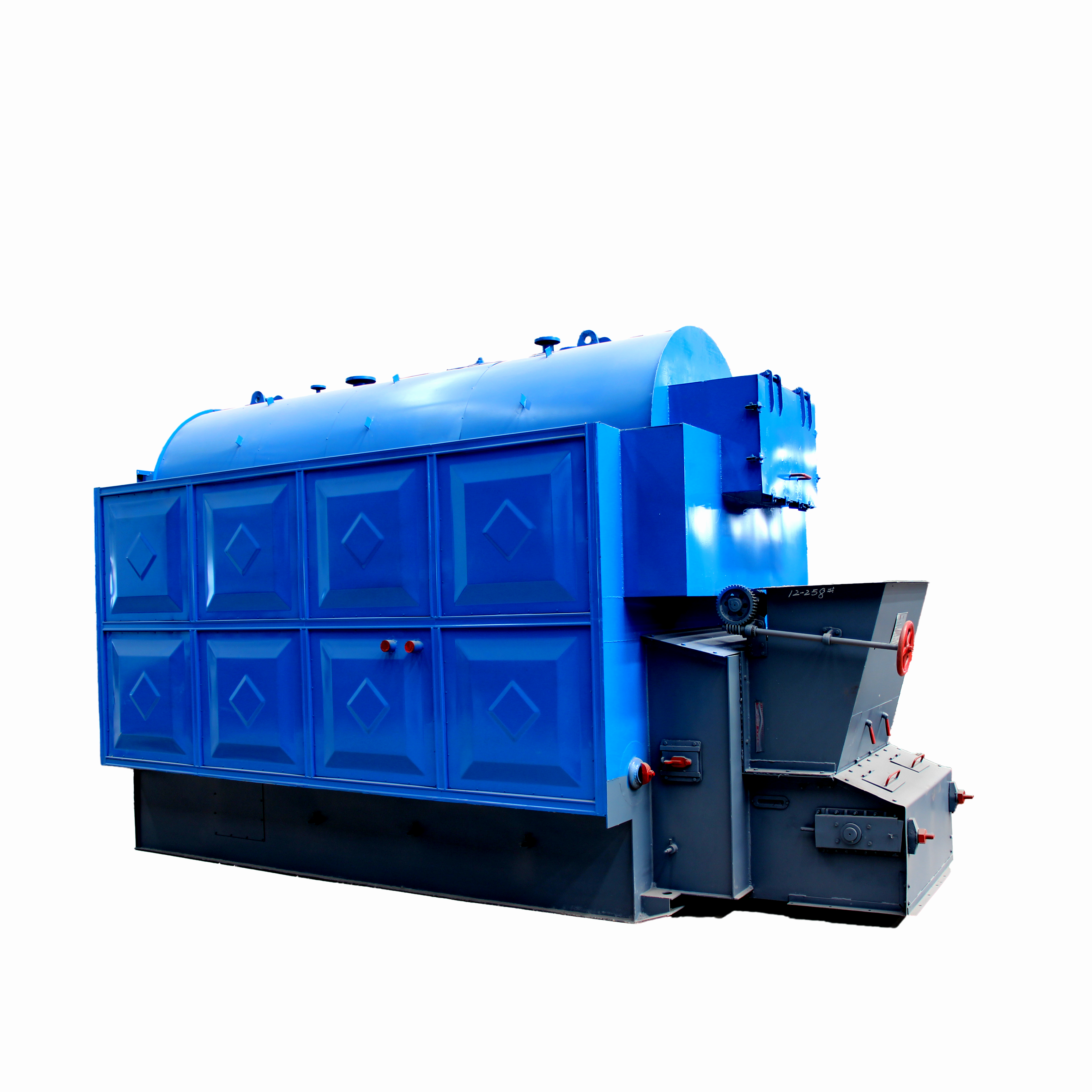

Product detail pictures:

Related Product Guide:

Boiler Structure

Dedicated to strict high-quality management and considerate shopper company, our experienced team associates are normally available to discuss your requirements and ensure full shopper gratification for Wholesale Fire Tube Boiler Manufacturer - Coal Boiler Biomass Boiler Water Flim Dust Cleaner – Double Rings , The product will supply to all over the world, such as: Bandung, Dominica, Slovenia, There are advanced producing & processing equipment and skilled workers to ensure the merchandise with high quality. We've got found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our merchandise are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.

Write your message here and send it to us