Leading Manufacturer for Bosch Boiler - Vertical Gas Oil Boiler – Double Rings

Leading Manufacturer for Bosch Boiler - Vertical Gas Oil Boiler – Double Rings Detail:

Introduction :

1. Compact structure, small installation area, easy to install.

2. Good heating surface , low exhaust gas temperature

3. The world famous original burner, automatic and high efficient combustion, high combustion efficiency

4. Microcomputer automatic controller, overpressure protection and ultra-low water level automatic protection and automatic feed water .

5. Super thickness insulating layer design, good insulation effect, boiler surface temperature low, low losing heating.

6. Small dust emission to achieve the requirements of the national environmental safety.

Steam Boiler Parameter

LHS Vertical Steam Boiler burning oil or gas

Main Technology Parameter List

| ModelItem | LHS0.1-0.4-YQLHS0.1-0.7-YQ | LHS0.2-0.4-YQLHS0.2-0.7-YQ | LHS0.3-0.4-YQLHS0.3-0.7-YQ | LHS0.5-0.4-YQLHS0.5-0.7-YQ | LHS0.7-0.4-YQLHS0.7-0.7-YQ | LHS1-0.4-YQLHS1-0.7-YQLHS1-1.0-YQ |

| Rated Capacity T/h |

0.1 |

0.2 |

0.3 |

0.5 |

0.7 |

1.0 |

| Rated Working Pressure |

0.4/0.7 Mpa |

0.4/0.7 Mpa |

0.4/0.7 Mpa |

0.4/0.7 Mpa |

0.4/0.7 Mpa |

0.4/0.7 Mpa |

| Rated Steam Temp. ℃ |

152/170 |

151.8/170 |

151.8/170 |

151.8/170 |

151.8/170 |

151.8/170/183 |

| Feed Water Temp. ℃ |

20 |

|||||

| Heating Surface m² |

2.3 |

4.34 |

6.53 |

12.05 |

20.93 |

25.48 |

| Installed Overall Dimension |

1.26×1.25×1.97 |

1.456×1.35×2.07 |

1.91×1.68×2.475 |

2.15×1.9×2.735 |

1.54×2.3×2.855 |

2.963×2.35×3.07 |

| Boiler Weight Ton |

1 |

1.15 |

1.67 |

2.57 |

2.96 |

4.03 |

| Water Pump Model |

JGGC 0.6-8 |

JGGC 0.6-8 |

JGGC 0.6-8 |

JGGC 0.6-12 |

JGGC 0.6-12 |

JGGC 2-10 |

| Chimney mm |

Ø 150 |

Ø 150 |

Ø 200 |

Ø 200 |

Ø 300 |

Ø 300 |

| Thermal Efficiency % |

83 |

83 |

83 |

83 |

83 |

83 |

| Design Fuel |

Light Oil/Town Gas/Natural Gas |

|||||

| Burner Brand` |

Italy RIELLO Burner G20S |

|||||

| Ringelmann shade |

< Grade 1 |

|||||

Hot Water Boiler Parameter

Atmospheric Pressure Hot Water Boiler burning gas or oil

Main Parameter List

|

Model Item |

CLHS0.21-95/ 70-Y(Q)

|

CLHS0.35-95/ 70-Y(Q)

|

CLHS0.5-95/ 70-Y(Q)

|

CLHS0.7-95/ 70-Y(Q)

|

CLHS1.05-95/ 70-Y(Q)

|

CLHS1.4-95/ 70-Y(Q)

|

|

Rated Thermal Power MW |

0.21 |

0.35 |

0.5 |

0.7 |

1.05 |

1.4 |

|

Rated Outlet Water Temp. ℃ |

95 |

|||||

|

Rated Return Water Temp. ℃ |

20 |

|||||

|

Design Fuel |

Heavy oil/0# Light Diesel oil/ Natural Gas |

|||||

|

Heating Surface m² |

10.5 |

12.6 |

15 |

16.5 |

22 |

35.6 |

|

Design Thermal efficiency |

83% |

|||||

|

Heating Area m² |

1800 |

3000 |

4300 |

6000 |

9000 |

12000 |

|

Boiler Body Specification mm |

Ø1164×2040 |

Ø1164×2550 |

Ø1264×2550 |

Ø1364×2360 |

Ø1468×2590 |

Ø1568×2830 |

|

Boiler Weight Ton |

1.7 |

1.9 |

2.5 |

3.0 |

3.1 |

3.8 |

|

Dust emission |

< 100 mg/Nm3 |

|||||

|

Ringelmann shade |

< Grade 1 |

|||||

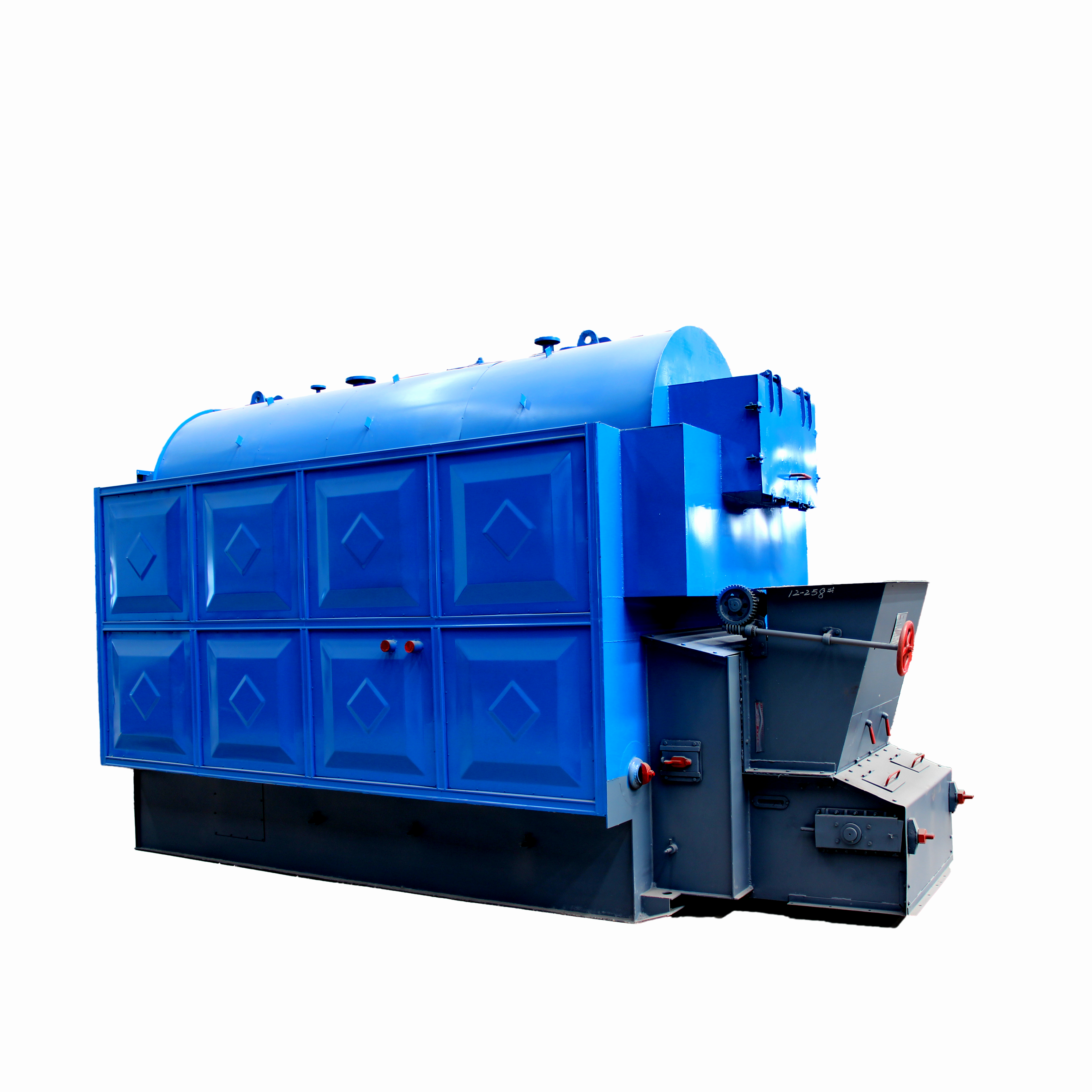

Product detail pictures:

Related Product Guide:

Boiler Structure

We attempt for excellence, support the customers", hopes to become the top cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes worth share and continual marketing for Leading Manufacturer for Bosch Boiler - Vertical Gas Oil Boiler – Double Rings , The product will supply to all over the world, such as: Benin, Palestine, Montpellier, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.