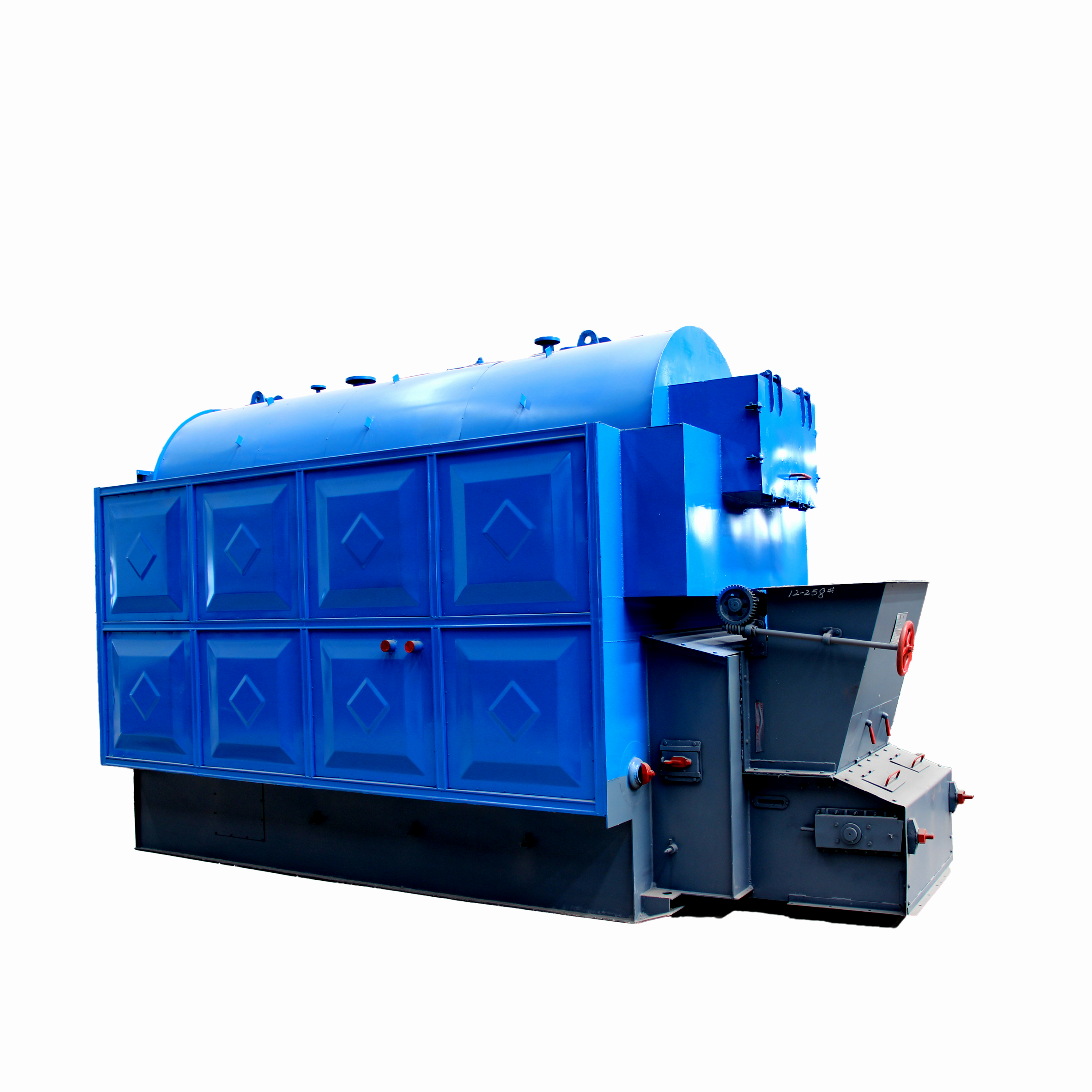

Single Drum Steam Boiler

Introduction :

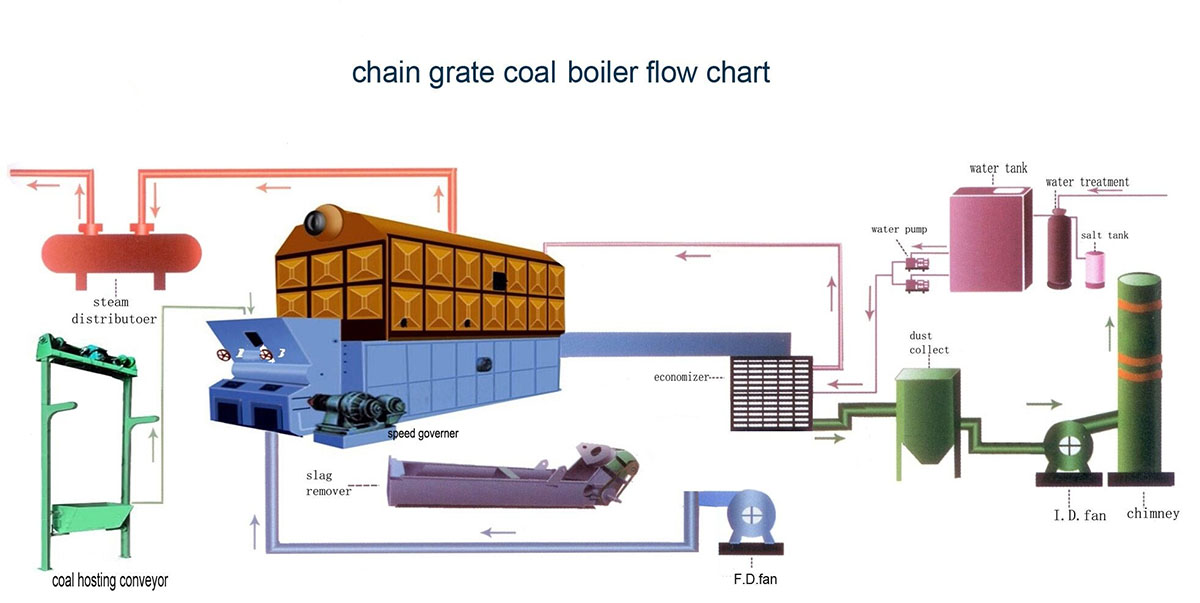

Single Drum Chain Grate Coal fired boiler is horizontal three-back water fire pipe composite boiler. Fix fire tube in drum and the light pipe water wall is fixed on the right and left sides of the furnace. With light chain grate stoker for mechanical feeding and by the draft fan and blower for mechanical ventilation, realize mechanical taphole by scraper slag remover.

The hopper of fuel drops to grate bar, then enter furnace for burning, by the ashes room above the back arch, the flame gets through the first backhaul fire tube to front smokebox, then turn back from front smokebox to the second flue for economizer and dust collector, at last, released into the atmosphere by the draft fan through chimney.

Parameter :

DZG(L)Horizontal Type Coal-Burning Steam Boiler

Main Technology Parameter List

| Model | DZG1-0.7-A II DZG1-1.0-A II DZG1-1.25-A II |

DZG2-1.0-A II DZG2-1.25-A II DZG2-1.57-AII |

DZG4-1.25-A II DZG4-1.57-A II |

DZL1-0.7-A II DZL1-1.0- A II DZL1-1.25- A II DZL1-1.57- A II DZL1-2.45- A II |

||

| Rated Capacity T/h | 1 | 2 | 4 | 1 | ||

| Rated Working Pressure Mpa | 0.7/1.0/1.25 | 1.0/1.25/1.57 | 1.25/1.57 | 0.7/1.0/1.25/1.57/2.45 | ||

| Rated Steam Temp. ℃ | 170/183/194 | 183/194/204 | 194/204 | 170/183/194/204/226 | ||

| Feed Water Temp. ℃ | 20 | 20 | 20 | 20 | ||

| Fuel Consumption Kg/H | 170 | 330 | 600 | 170 | ||

| Thermal Efficiency % | 77 | 77 | 78 | 78 | ||

| Heating Surface m² | Boiler Body | 32.4 | 33.85 | 75.75 | 32.4 | |

| Economizer | 12.51 | 24.64 | 38.5 | 12.51 | ||

| Grate area m² | 1.37 | 2.3 | 2.05 | |||

| Designed Fuel Type | Bituminous Coal | Bituminous Coal | Bituminous Coal | Bituminous Coal | ||

| Max. Transport Weight T | 10.6 | 19.6 | 26.5 | 13.3 | ||

| Max. Transport Dimension m | 4.75x2.1x2.6 | 5.7x3.4x4.6 | 5.49x2.6x3.5 | 5.65x2.1x2.6 | ||

| Boiler Auxiliary Equipment Model and Specification | ||||||

| Air Blower | Model | T4-72-11;3.2A;Right225° | T4-72-11;3.2A;Righ 315° | T4-72-11;4A; Right 315° | T4-72-11;3.2A; Right 225° | |

| Motor Power | N=1.5 Kw | N=3 Kw | N=5.5 Kw | N=1.5 Kw | ||

| Draft Fan | Model | YX9-35-11;5C ; Right 0° | Y-9-26;6.3C ; Right 0° | Y-9-26;9D;Right 0° | YX 9-35-11;5C; Right 0° | |

| Motor Power | N=5.5 Kw | N=11 Kw | N=22 Kw | N=5.5 Kw | ||

| Gear Box | Model | GL-5P | ||||

| Motor Power | N=0.55 Kw | |||||

| Feed Water Pump | Model | 1.5WCT-120 | 1½ GC5x7 | 1½ GC5x7 | 1.5WCT-120 | |

| Motor Power | N=2.2 Kw | N=7.5 Kw | N=7.5 Kw | N=2.2 Kw | ||

| Dust Remover | Model | XD-1 | XD-2 | XD-4 | XD-1 | |

| Model | DZL2-1.0-AII DZL2-1.25-AII DZL2-1.57-AII DZL2-2.45-AII |

DZL4-1.25-AII DZL4-1.57-AII DZL4-2.45-AII |

DZL6-1.25-AII DZL6-1.57-AII DZL6-2.45-AII |

DZL8-1.57-AII | DZL10-1.25-AII DZL10-1.57-AII DZL10-2.45-AII |

|||

| Rated Capacity T/h | 2 | 4 | 6 | 8 | 10 | |||

| Rated Working Pressure Mpa | 1.0/1.25/1.57/2.45 | 1.25/1.57/2.45 | 1.25/1.57/2.45 | 1.57 | 1.25/1.57/2.45 | |||

| Rated Steam Temp. ℃ | 183/194/204/226 | 194/204/226 | 194/204/226 | 203.04 | 194/204/226 | |||

| Feed Water Temp. ℃ | 20 | 20 | 20/60 | 20 | 20/60 | |||

| Fuel Consumption Kg/H | ~310 | ~590 | ~900 | ~1200 | ~1440 | |||

| Thermal Efficiency % | 78 | 80 | 77.44 | 78 | 80.6 | |||

| Heating Surface m² | Boiler Body | 33.85 | 75.75 | 142 | 205 | 347 | ||

| Economizer | 24.64 | 38.5 | 87.2 | 139.52 | ||||

| Grate area m² | 3.5 | 4.66 | 7.4 | 8.4 | 10.98 | |||

| Designed Fuel Type | Bituminous Coal | Bituminous Coal | Bituminous Coal | Bituminous Coal | ||||

| Max.Transport Weight Ton | 21 | 26.5 | 38 | 33 | 28/29 | |||

| Max. Transport Dimension m | 5.9x2.2x3.3 | 6.5x2.6x3.524 | 7.4x3.2x4.2 | 8.1x3.2x4.2 | 7.6x3.2x3.5 | |||

| Boiler Auxiliary Equipment Model and Specification | ||||||||

| Air Blower | Model | T4-72-11;3.2A;Right315° | T4-72-11;4A;Righ 315° | T4-72-11;5A; Right 225° | GG8-Na;7.1A; Right 225° | 10TG811DRight 225° | ||

| Motor Power | N=3 Kw | N=5.5 Kw | N=11 Kw | N=11 Kw | N=15 Kw | |||

| Draft Fan | Model | Y9-26;6.3C; Right 0° | Y-9-26;9D; Right 0° | Y-8-39;9D;Right 0° | GY8-1;Na9.5D;Right 0° | 10JY;9.5D; Right 0° | ||

| Motor Power | N=11 Kw | N=22 Kw | N=30Kw | N=37Kw | N=45 Kw | |||

| Gear Box | Model | GL-5P | GL-5P | GL-10P | GL-16P | |||

| Motor Power | N=0.55 Kw | N=0.55 Kw | N=1.1 Kw | N=1.1 Kw | ||||

| Feed Water Pump | Model | 1½ GC 5x7 | 1½ GC 5x7 | DG 6-25x7 | 2GC-5xT | 1½ GC 6x6 | ||

| Motor Power | N=7.5 Kw | N=7.5 Kw | N=7.5 Kw | N=22 Kw | N=2.2 Kw | |||

| Dust Remover | Model | XD-2 | XD-4 | XD-6 | XD-8 | XD-10 | ||